FANUC, Doosan Develop CNC Training Program

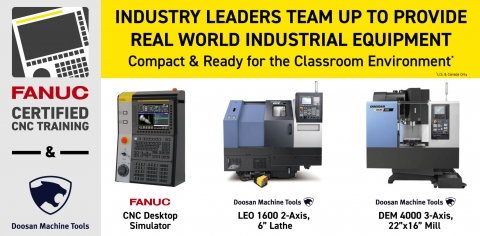

Rochester Hills, MI – (April 15, 2021) – FANUC America, a leading factory automation solutions provider, and Doosan Machine Tools America, a leading provider of CNC machine tools, are working together to build the next generation of machinists. The FANUC Certified CNC Training Program now offers manufacturing skills development using Doosan machine tools.

The new offering adds to the depth and breadth of FANUC’s CNC training tools and allows operators a hands-on experience with Doosan’s high-performance CNC machines, which have been used in manufacturing for over 40 years. The agreement is in collaboration with the FANUC Education Authorized Reseller Network and the Doosan Machine Tools Distributor Network. Together, they will provide industry-recognized training and equipment to educational institutions.

“Our collaboration will provide secondary and post-secondary schools with hands-on skill development, and industry-recognized certifications using world-class Doosan machine tools combined with FANUC’s industry-leading CNC controls,” said Paul Aiello, Director of Education, FANUC America. “We look forward to seeing students and job seekers develop the skills that will help them obtain exciting and high-paying careers in manufacturing.”

The primary machines offered to education providers will be the DEM 4000 3-axis vertical machining center and the LEO 1600 turning center. Although both of these machines are ideally suited for the existing FANUC CNC Milling and Turning curriculum, additional Doosan machine tools will be offered through FANUC’s exclusive Authorized Reseller Network in the future.

“Doosan is forming an alliance with one of the most respected companies in machine tools,” says Jim Shiner, VP of Sales & Marketing with Doosan. “The alliance with FANUC helps to strengthen Doosan’s continued commitment to education.”

In the future, FANUC’s Certified CNC Training Program will add digital twins of Doosan’s DEM 4000 and the LEO 1600 machine tools to the CNC Simulators with Machining Simulation software. This virtualized offering will be an effective tool for those learning how to run and program the Doosan machine tools without any risk to physical machines.