PolyJet Technology

3D Print Precision Prototypes in a Wide Range of Materials

PolyJet 3D printing technology is a powerful additive manufacturing method patented by Stratasys.

PolyJet technology 3D prints in the widest variety of materials, so you can create ergonomic tooling, bio-compatible surgical guides, or realistic prototypes that closely resemble finished products.

3D printers powered by PolyJet technology feature 16-micron layers with accuracy as high as 0.1 mm for smooth surfaces, thin walls, and complex geometries. It is the only technology that supports a range of materials with properties from rubber to rigid and transparent to opaque. And with Objet Connex technology, multiple materials can even be printed simultaneously in the same part.

Color and Multi-Material 3D Printing

The most advanced PolyJet systems, Objet Connex 3D Printers, combine diverse 3D printing materials in one model by jetting multiple materials simultaneously. This means you can selectively position multiple materials in one printed prototype and even combine two or three materials to create composite digital materials with distinct, predictable properties. Examples include rigid and rubberlike with a range of Shore A values in between; or cyan, magenta, and yellow with a range of blended hues.

With hundreds of digital material combinations and colors to choose from, PolyJet technology gives you better final-product realism than any other 3D printing method.

PolyJet Materials

Precision prototypes in over 100 materials.

PolyJet technology 3D prints in the widest variety of materials, so you can create realistic prototypes that closely resemble finished products.

Resources

Materials Data Sheet Systems & Materials Matrix Systems and Materials Overview

White Papers

PolyJet Materials Adding Chemical Resistance to PolyJet PrototypesHow PolyJet 3D Printing Works

PolyJet 3D printing is similar to inkjet document printing, but instead of jetting drops of ink onto paper, PolyJet 3D Printers jet layers of liquid photopolymer onto a build tray and instantly cure them with UV light. The fine layers build up to create a precise 3D model or prototype. Models are ready to handle and use right out of the 3D printer, with no post-curing needed. Along with the selected model materials, the 3D printer also jets a gel-like support material specially designed to uphold overhangs and complicated geometries. It is easily removed by hand or water.

PolyJet 3D Printing technology offers many rapid-prototyping advantages, including astonishingly fine detail, smooth surfaces, speed, and precision. The technology works with many materials, including Rigid Opaque in hundreds of vibrant colors, clear and tinted translucent shades, Rubber-like materials, Simulated Polypropylene, and specialized photopolymers for 3D printing in medical industries.

PolyJet 3D Printing Benefits

PolyJet technology creates precise prototypes that set the standard for finished-product realism. Its fine resolution makes complex shapes, intricate details and smooth surfaces possible. Objet Connex 3D Printers offer more material versatility than any other technology, including the ability to incorporate color and diverse materials into one model.

See also:

PolyJet 3D Printers FDM Technology SAF Technology Rapid PrototypingAgilus30

Agilus30 is an advanced PolyJet material designed to create flexible parts. The parts Agilus30 produces are flexible, yet strong parts making a wide range of colors and Shore A values possible with its three colors - clear, black and white.

Printers Supporting This Material

- Objet 260 Connex 1-2

- Stratasys J750 - black, clear and white

- J4100 - black, clear and white

- J826 Prime / J835 Prime / J850 Prime / J850 Pro

Top User Applications

- Medical Models

- Tooling needing rubber-like characteristics

- Consumer Goods

- Sporting Goods

- General Prototyping

- Overmolding

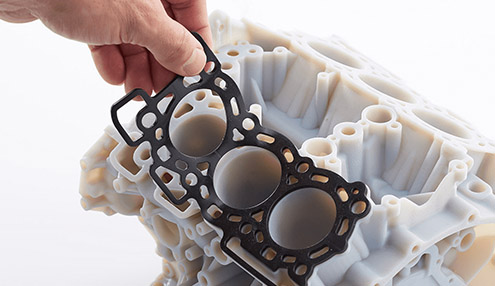

Digital ABS Plus & Digital ABS2 Plus (RGD515 Plus & RGD535)

3D Print Tough, Heat-Resistant Prototypes and Tooling

Digital ABS Plus and Digital ABS2 Plus benefit from the materials newly improved mechanical performance. Parts made with Digital ABS Plus and Digital ABS2 Plus will have better impact strength in addition to its previously well-known attributes of high-temperature resistance, toughness and superior finish.

Use Digital ABS2 Plus when thin, rigid walls are necessary.

Printers Supporting This Material

- J4100

- Stratasys J750

- Objet 26 Connex3

- Legacy Connex Printers

Top User Applications

- Functional Prototyping

- Manufacturing Tools

- Molds, including injection molds

- Snap-fit parts for high or low temperature use

- Electrical parts, casings, mobile phone casings

- Engine parts and covers

Simulated Polypropylene (Durus)

3D Print Tough, Heat-Resistant Prototypes and Tooling

Durus (RGD430) is the original simulated polypropylene material and exhibits great impact resilience and an elongation at break of 44%.

Printers Supporting This Material

- Objet30

- Objet30 Pro and Prime

- Objet Eden260VS

- Objet260 Connex1-3

- J4100

Top User Applications

- Prototypes of all kinds

- Snap-fit assemblies

- Living Hinges

- Testing form, fit and function

Rigur (RGD450): Simulate the Appearance and Functionality of Polypropylene

Rigur, an advanced simulated polypropylene, offers durability and a smooth finish. 3D print precision prototypes that look and behave like polypropylene. Rapidly create models to test form, fit and function for snap-fit assemblies, living hinges and durable housings and packaging.

Printers Supporting This Material

- Objet30 Pro and Prime

- Objet Eden260VS

- Objet260 Connex1-3

- J4100

Top User Applications

- Prototypes of all kinds

- Snap-fit assemblies

- Living Hinges

- Testing form, fit and function

High Temperature (RGD525)

High Temperature material (RGD525, white) combines heat resistance with exceptional dimensional stability. The material can simulate the thermal performance of engineering plastics and is ideal for testing applications such as hot-air flow or hot-water flow in pipes and faucets.

Printers Supporting This Material

- Objet30 Pro and Prime

- Objet Eden260VS

- Connex3 Printers

Top User Applications

- Form, fit and thermal functional testing of static parts

- Heat resistant jigs and fixtures

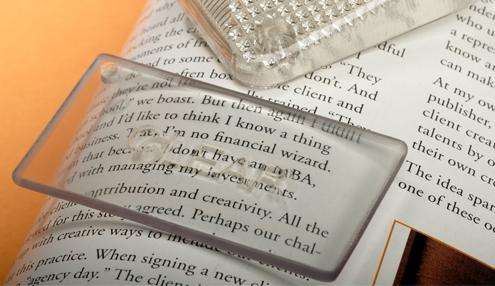

Transparent (RGD720), VeroClear (RGD810), VeroUltraClear (RGD820) & VeroUltraClearS (RGD821)

Transparent material (RGD720) is a multipurpose transparent PolyJet photopolymer for standard clear plastics simulation. It combines high dimensional stability with surface smoothness.

Transparent material (VeroClear-RGD810) is a rigid, nearly colorless material featuring proven dimensional stability for general purpose, fine-detail model building, and visual simulation of transparent thermoplastics such as PMMA.

Transparent PolyJet digital material (VeroUltraClear-RGD820) simulates acrylic, achieving 95% light transmission of that material, and is useful for prototypes of glass, clear polymers, or transparent packaging. Improves upon past performance of VeroClear-RGD810 with a higher clarity, transparency, and a lower yellow index.

VeroUltraClearS (RGD821) is a high-clarity and transparent material that simulates PMMA. It has improved translucency compared to VeroClear and is a single-material channel solution. It is easy to post-process and polish and also use with CMY materials as an enabler.

Printers Supporting This Material

- J4100 (VeroClear-RGD810)

- Objet30 Pro (VeroClear-RGD810)

- Objet30 Prime (VeroClear-RGD810 | RGD720)

- Objet Eden260VS (VeroClear-RGD810 | RGD720)

- Objet260 Connex1-3 (VeroClear-RGD810 | RGD720)

- Stratasys J750 (VeroClear-RGD810 | RGD720 | VeroUltraClear-RGD820)

- Stratasys J750 Digital Anatomy (VeroClear-RGD810 | RGD720 | VeroUltraClear-RGD820)

- J850 and J835 (VeroClear-RGD810 | VeroUltraClear-RGD820)

- J55 (VeroClear-RGD810 | VeroUltraClearS-GD821)

Top User Applications

- Form and fit testing of clear or see-through parts

- Medical applications

- Artistic and exhibition modeling

- Packaging prototypes

- Eyewear or lighting component prototypes

- Medical or manufacturing applications

Rubber-like Tango & TangoPlus

Build Soft-Touch, Flexible Prototypes

Create realistic prototypes with flexible, rubber-like qualities. Tango simulates soft-touch coatings, nonslip surfaces, rubber surrounds or overmolding. Test and verify grips, pulls, handles, gaskets or footwear in a range of Shore A values comparable to rubber bands, tire treads, and shoe heels.

Rubber-like PolyJet photopolymers can simulate rubber with different hardness levels, elongation, and tear resistance. Gray, black, white, and translucent, Rubber-like material can simulate a very wide variety of finished products, from soft-grip handles to footwear. With Stratasys J750 and Connex3 systems, you can add color to the mix for exceptional final-product realism.

- Rubber-like gray (TangoGray FLX950)

- Rubber-like black (TangoBlack FLX973)

- Rubber-like translucent (TangoPlus FLX930)

- Rubber-like advanced black (TangoBlackPlus FLX980)

Printers Supporting This Material

- Objet30 Prime

- Objet Eden260VS

- Objet260 Connex1-3

- Stratasys J750

- J4100

Combine Tango with Rigid Opaque (Vero) to simulate nine Shore A values from Shore 27 to Shore 95.

Top User Applications

- Exhibition and communication models

- Rubber surrounds and over-molding

- Soft-touch coatings and non-slip surfaces for tooling or prototypes

- Knobs, grips, pulls, handles, gaskets, seals, hoses, footwear

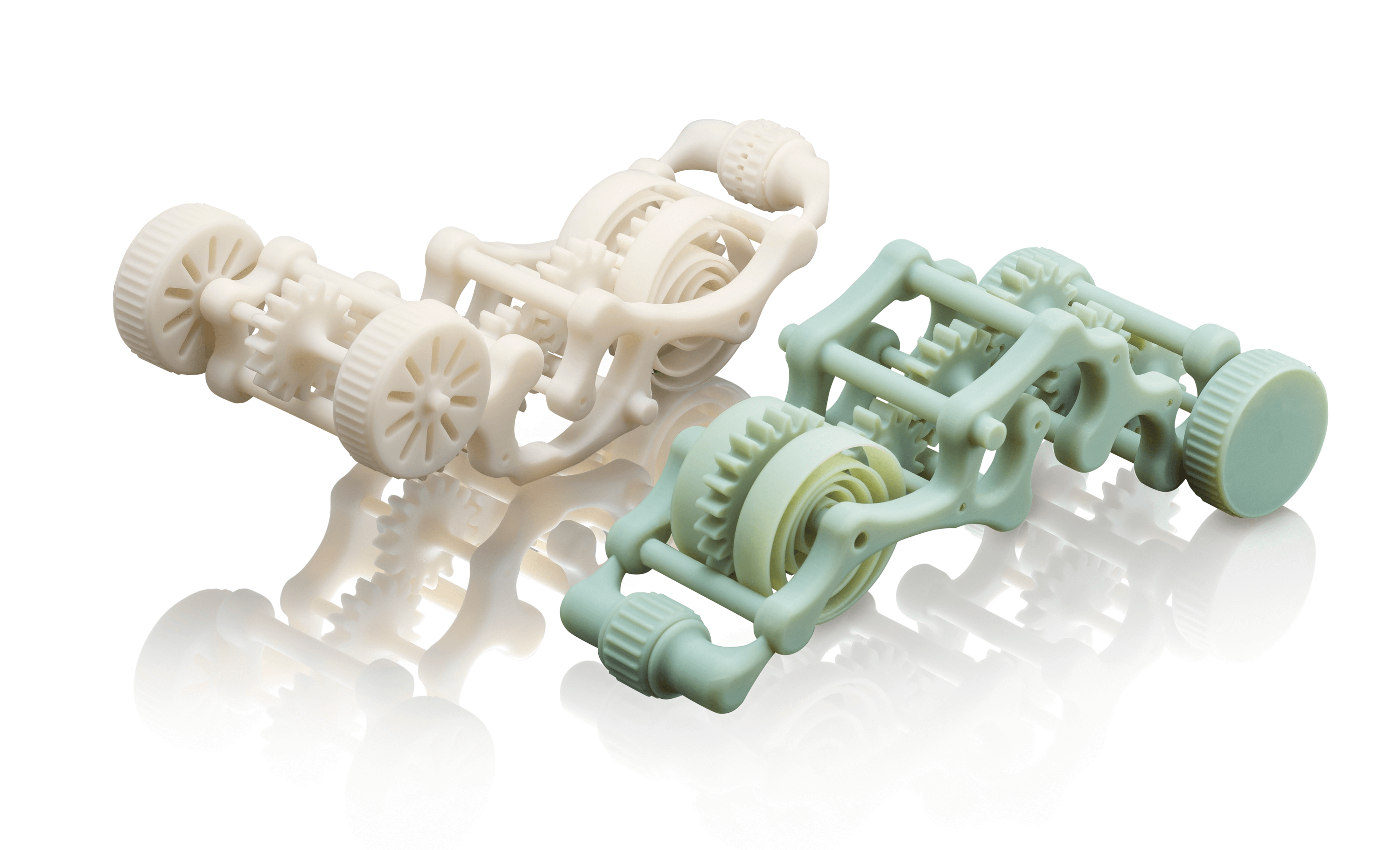

Rigid Opaque (Vero) and Vero Vivid Colors

Realistic, Multi-Color Prototypes in Less Time

PolyJet Vero Materials are rigid opaque photopolymers that provide excellent detail visualization and can be blended with other photopolymers to vary hardness, flexibility, translucency or heat resistance.

For brighter colors, try the Vero Vivid Colors - VeroCyanV, VeroMagentaV and VeroYellowV.

Printers Supporting This Material

- Objet30 Prime

VeroBlackPlus (RGD875), VeroBlue (RGD840), VeroGray (RGD850), VeroWhitePlus (RGD835) - Objet Eden260VS

VeroBlackPlus (RGD875), VeroBlue (RGD840), VeroGray (RGD850), VeroWhitePlus (RGD835) - Objet30 Pro

VeroBlackPlus (RGD875), VeroBlue (RGD840), VeroGray (RGD850), VeroWhitePlus (RGD835) - Connex3 Printers

VeroBlackPlus (RGD875), VeroCyan (RGD841), VeroBlue (RGD840), VeroGray (RGD850), VeroMagenta (RGD851), VeroWhitePlus (RGD835), VeroYellow (RGD836) - Stratasys J750/J735

VeroBlackPlus (RGD875), VeroCyan (RGD841), VeroBlue (RGD840), VeroGray (RGD850), VeroMagenta (RGD851), VeroYellow (RGD836), Vero PureWhite (RGD837) (A brilliant white - 20 percent brighter than VeroWhitePlus with twice the opacity, with outstanding versatility and fine detail), Vivid Colors - VeroMagentaV, VeroYellowV, VeroCyanV, VeroFlex Colors - VeroFlex Cyan, VeroFlex Magenta, VeroFlex Yellow, VeroFlex White, VeroFlex Black and VeroFlex Clear; VeroFlexVivid Colors - VeroFlexVivid-Magenta, VeroFlexVivid-Yellow, and VeroFlexVivid-Cyan.

Top User Applications

- Moving components or assemblies

- Functional Prototyping

- Jigs & Fixtures

- Tooling

Transparent (RGD720), VeroClear (RGD810) & VeroUltraClear (RGD820)

Transparent material (RGD720) is a multipurpose transparent PolyJet photopolymer for standard clear plastics simulation. It combines high dimensional stability with surface smoothness.

Transparent material (VeroClear-RGD810) is a rigid, nearly colorless material featuring proven dimensional stability for general purpose, fine-detail model building and visual simulation of transparent thermoplastics such as PMMA.

Transparent PolyJet digital material (VeroUltraClear-RGD820) simulates acrylic, achieving 95% light transmission of that material, and is useful for prototypes of glass, clear polymers, or transparent packaging. Improves upon past performance of VeroClear-RGD810 with a higher clarity, transparency, and a lower yellow index.

Printers Supporting This Material

- Objet1000 Plus (VeroClear-RGD810)

- Objet30 Pro (VeroClear-RGD810)

- Objet30 Prime (VeroClear-RGD810 and RGD720)

- Objet Eden260VS (VeroClear-RGD810 and RGD720)

- Connex3 Printers (VeroClear-RGD810 and RGD720)

- Stratasys J750 (VeroClear-RGD810 and RGD720)

- J850 and J835 (VeroClear-RGD810 and VeroUltraClear-RGD820)

Top User Applications

- Form and fit testing of clear or see-through parts

- Medical applications

- Artistic and exhibition modeling

- Packaging prototypes

- Eyewear or lighting component prototypes

- Medical or manufacturing applications

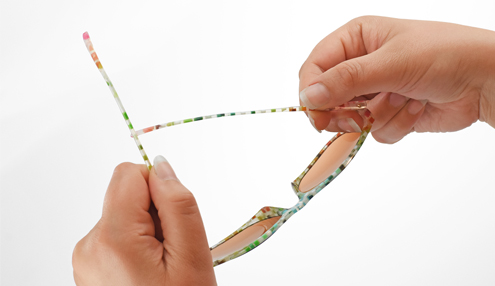

VeroFlex and VeroFlexVivid

Create Accurate, Flexible Eyewear Prototypes

Gain the competitive edge by bringing new ideas and designs to market...fast. Stratasys’ VeroFlex material has been designed to meet the unique prototyping needs of eyewear manufacturers, and shortens the product development cycle from 18 months to 1-2 months.

For brighter colors, try the VeroFlexVivid Colors - VeroFlexVivid-Magenta, VeroFlexVivid-Yellow, and VeroFlexVivid-Cyan.

Printers Supporting This Material

- Stratasys J750

Bio-compatible (MED610)

Bio-compatible PolyJet photopolymer (MED610) is a rigid medical rapid prototyping material. It features high dimensional stability and colorless transparency. The material is ideal for applications requiring prolonged skin contact of more than 30 days and short-term mucosal-membrane contact of up to 24 hours.

VeroUltra Opaque

The Vero Opaque family adds high-quality color to all parts and prototypes.

Opaque materials facilitate the printing of thin parts, providing richer colors with sharper textures and texts.

When combined as digital materials with other Stratasys PolyJet materials such as VeroWhite, VeroUltraClear, or the Agilus30 family the possibilities become endless!

Create high-quality color objects with professional, realistic finishes applying sharp graphic and text capabilities.

Printers Supporting This Material

- J7 Series

- J8 Series

- J55

Top User Applications

- Consumer Goods

- Consumer Electronics

- Automotive /Transportation

- Toys / Figurines

- Packaging