Bayport Oil & Gas Training Solutions

Oil & gas are vital to the modern world for fuel, as well as the production of a wide variety of products such as solvents, plastics, pharmaceuticals, and more. Bayport Technical offers Oil & Gas training solutions focused on important processes critical for oil & gas training programs.

Bayport Technical's Oil & Gas products will be instrumental in preparing learners for careers throughout a variety of energy-related industries. These Oil & Gas training aids allow learners to gain hands-on experience with real-world components that they'll see in real industry facilities.

Training Systems

Bayport Technical's Oil & Gas trainers teach important skills needed by employers in the oil & gas industry.

140-GLPT | Gas Lift Process Trainer

Bayport Technical's Gas Lift Process Trainer (140-GLPT) was designed specifically to illustrate the injection of gas into the production piping of wells with inadequate formation pressure to flow independently. The unit contains multiple regulators, valves, and gauges to allow for broad training opportunities associated with the up-steam arena.

Cutaways

Bayport Technical's Cutaways allow individuals to see and identify the internal components of pumps, valves, and other industrial equipment. Components can be taken apart and reassembled for training purposes. NOTE: Pictures of cutaway models are representative of our products; actual equipment, size, and color scheme may vary with each piece according to availability and customer preference.

108-AOBV | Air Operated Ball Valve Cutaway

Bayport Technical's Air Operated Ball Valve Cutaway (108-AOBV) allows individuals to see and identify the internal components of the valve. The valve can be taken apart and reassembled for training purposes.

108-CPS | Centrifugal Pump Skid Cutaway

Centrifugal pumps are mechanical devices designed to move fluids through the transfer of rotational energy from one or more driven rotors, called impellers. Fluid enters the rapidly-rotating impeller along its axis and is cast out by centrifugal force along its circumference through the impeller’s vane tips. Bayport Technical's Centrifugal Pump Skid Cutaway allows individuals to see and identify the internal components of a centrifugal pump and electrical motor.

108-PRV | Pressure Release Valve Cutaway

Bayport Technical's Pressure Release Valve Cutaway (108-PRV) allows individuals to see and identify the internal components of the valve. The valve can be taken apart and reassembled for training purposes.

108-SRP | Steam Reciprocating Pump Cutaway

Reciprocating pumps tend to be used in low-flow, high-pressure applications. These positive displacement pumps can include both diaphragms and pistons to supply pumping action while valves regulate flow in and out of the pump. They can vary greatly in size, from large scale power pumps to small pressure-washer units.

Bayport Technical's Steam Reciprocating Pump Cutaway (108-SRP) allows individuals to see and identify the internal components of the pump. The cutaway can be taken apart and reassembled for training purposes.

108-TSPV | Twin Seal Plug Valve Cutaway

With one double-seated bubble-tight valve, the twin seal plug valve serves as an alternative to a traditional two-valve system. The upstream and downstream seals provide the same function as two block valves. The body serves as a spool piece, and the body bleed verifies seal integrity.

118-IBST | Inverted Bucket Steam Trap Cutaway

Bayport Technical's Inverted Bucket Steam Trap Cutaway (118-IBST) allows individuals to see and identify the internal components of the steam trap. The steam trap can be taken apart and reassembled for training purposes.

118-ILCV | In-Line Check Valve Cutaway

In-line check valves are simple in both concept and function. They are designed to allow flow of fluid or gas in one direction while blocking flow in the opposite direction.

These valves are common parts of fluid power circuits, which usually require a one-way flow path. Convenient and versatile, in-line check valves are useful in a wide variety of applications.

118-TFST | Thermostatic Float Steam Trap Cutaway

Thermostatic float steam traps are mechanical devices that operate on both density and temperature principles. A thermostatic vent in the top of the trap allows free passage of air during start-up, and closes near saturation temperature. Condensate fills a float chamber, causing a float to rise, and through a lever mechanism pulls a valve off its seat and opens the orifice of a discharge valve. The opening and closing of the seat provides modulation to handle light or heavy condensate loads.

128-FAPC | Foxboro 43 AP Controller Cutaway

The Foxboro 43 AP pneumatic controller is a versatile process instrument controller that can be used to control pressure, temperature, flow, and level. It continuously detects the difference between a process measurement and its set point and produces an output air signal that is a function of this difference and the type of control.

128-MFM | Magnetic Flow Meter Cutaway

Magnetic flow meters are popular because they are cost-effective, bi-directional, and highly accurate. They are used for a wide variety of applications across a broad range of industries, including: pulp and paper; metals and mining; water and wastewater; food and beverage; chemical and petrochemical; and oil and gas.

150-LGR | Lubricated Gear Reducer Cutaway

Gear (or speed) reducers (also commonly referred to as gear drives) tend to be extremely durable pieces of equipment even in the most severe applications. Because friction is created between internal moving components in a gear reducer, oil is used to minimize friction and wear, dissipate heat, and lubricate bearings and seals.

Working Demonstrators

Bayport Technical's Oil & Gas working demonstrators teach skills related to three-phase separators, cooling towers, and floating roof tanks. Contact Bayport Technical today for more information!

142-3PS | 3 Phase Separator Working Demonstrator – Acrylic

Bayport Technical's 3 Phase Separator Working Demonstrator - Acrylic (142-3PS) simulates the crude oil production process of separating water, oil, and gas before it is shipped to an oil refinery. This hands-on, see-through 3-phase separator training system continuously mixes air, water, and a hydrocarbon-based fluid that allows learners to understand the flow and gravity separation in this essential oil and gas industry application.

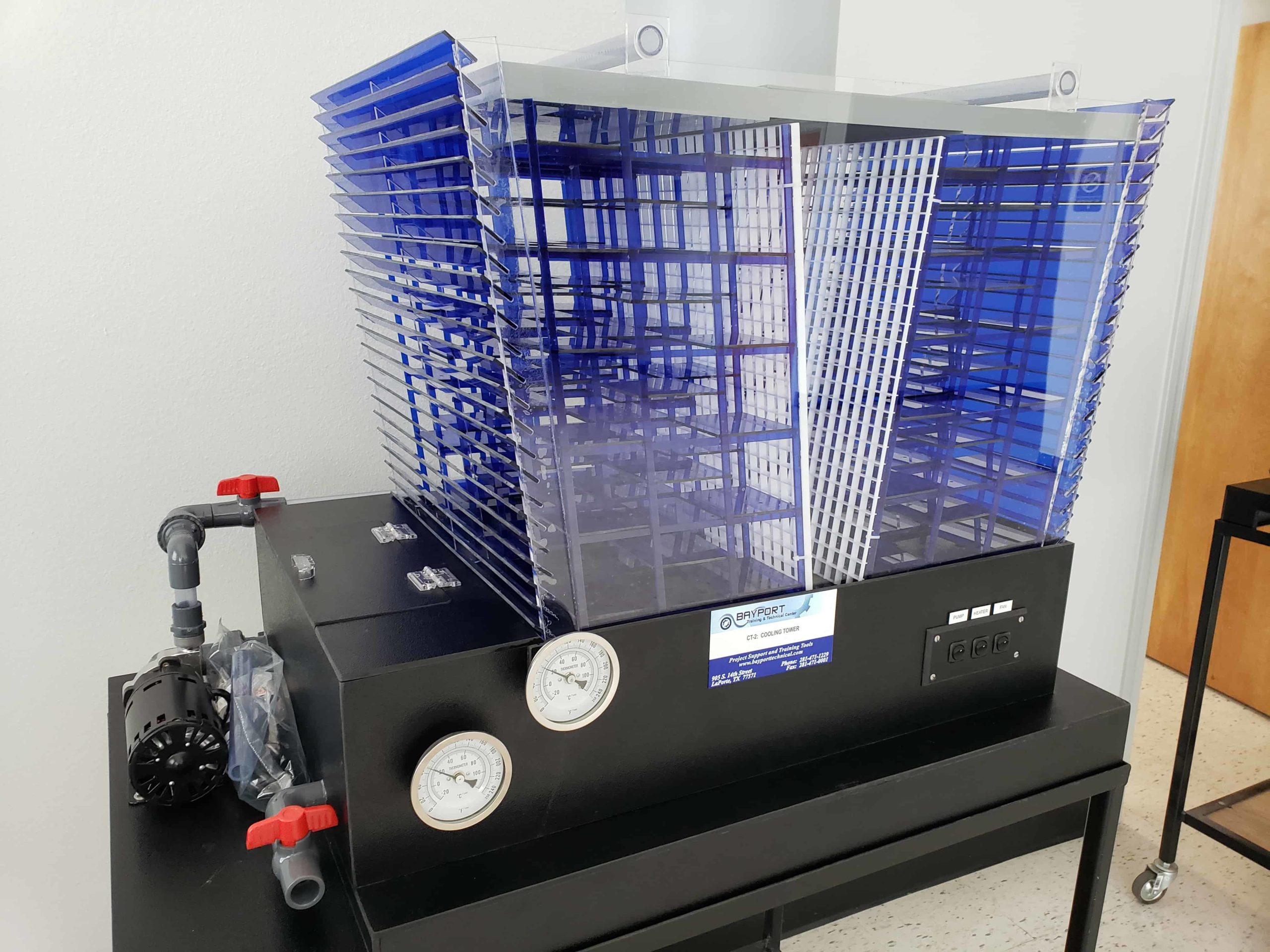

142-CT2 | Cooling Tower Working Demonstrator

Includes a heater and gauges. Oil refineries and petrochemical plants use water to cool down the high temperatures that are generated by the particular processes they use. This model is made of acrylic to allow full view of the water flow through the tower. This table top working model includes an induction fan, heater, circulation pump, mist maker, and tank.

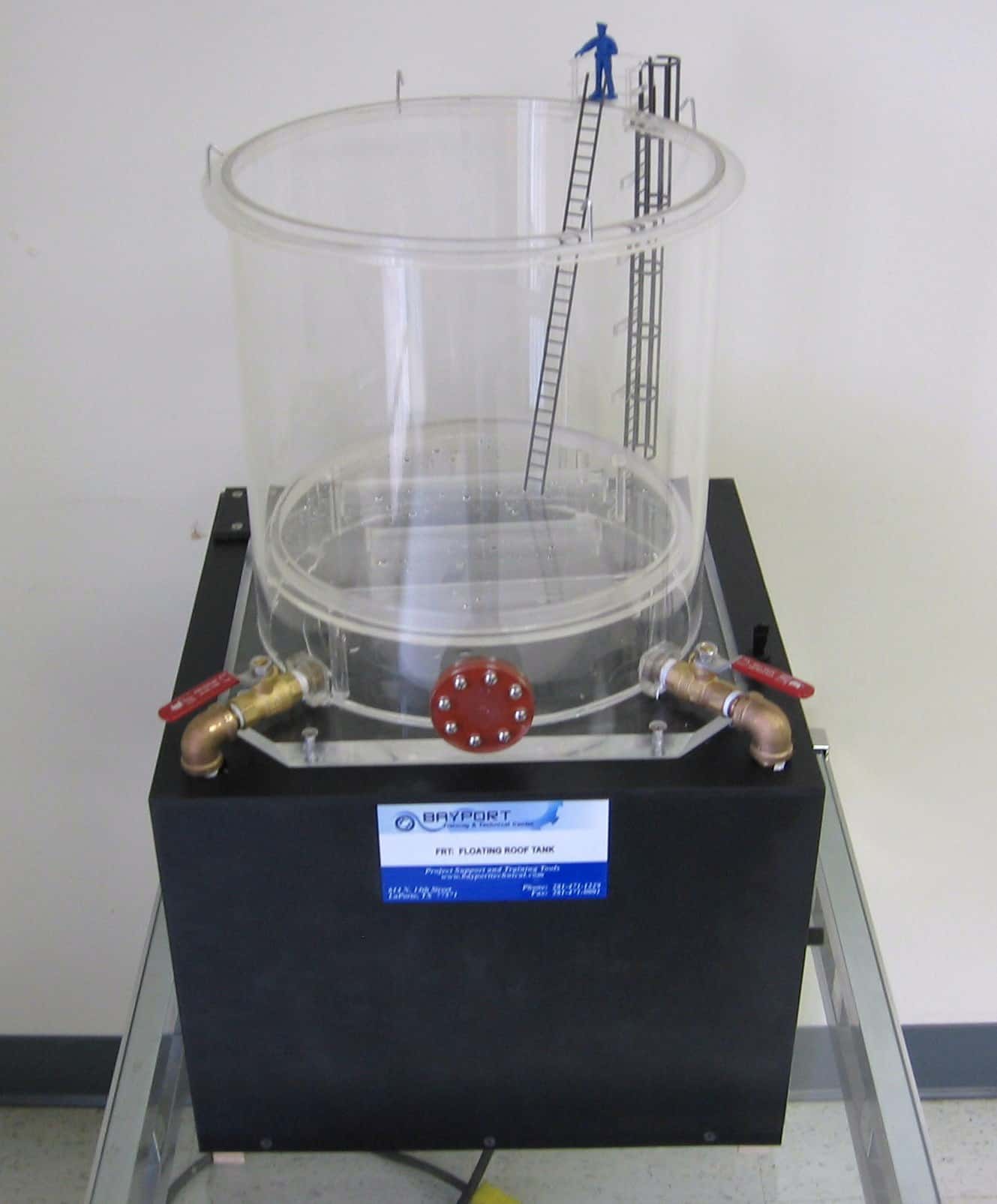

142-FRT | Floating Roof Tank Working Demonstrator

This model demonstrates the dynamics of a floating roof and what is required to lift the roof in some of the tanks you find in today’s refineries and petrochemical plants.