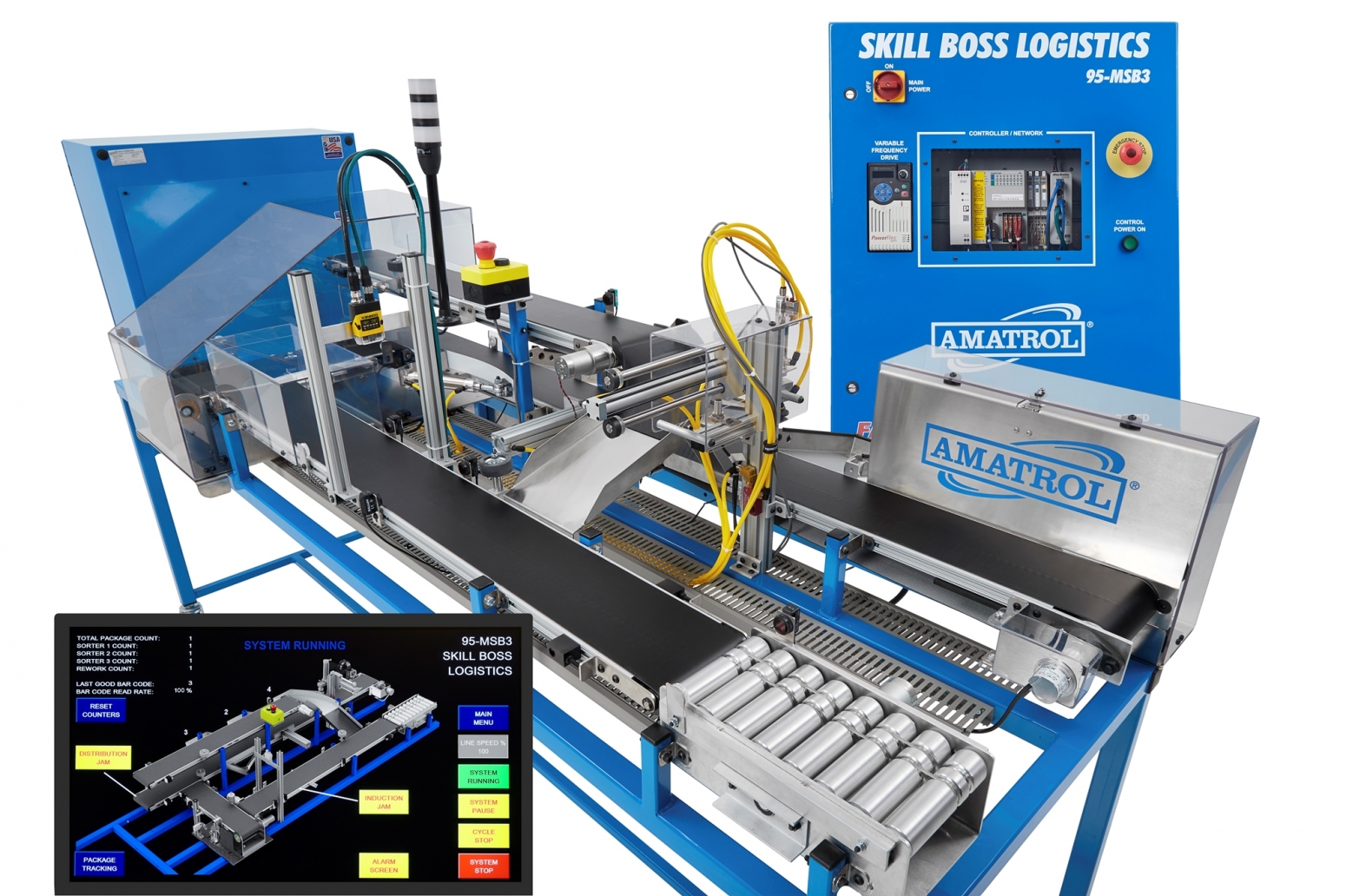

Amatrol Skill Boss Logistics

Amatrol’s Skill Boss Logistics (95-MSB3) offers a performance-based assessment for evaluating material handling skill levels and competencies of supply chain automation technicians. The Skill Boss Logistics is a working automated distribution system that performs operations, such as package tracking, automatic package queuing and priority release, electro-pneumatic sorting, and more. In addition to industrial-relevant training, the Skill Boss Logistics is the required assessment device for three of MSSC’s Certified Technician – Supply Chain Automation (CT-SCA) certifications: Equipment Maintenance (CTSCA-EM), Equipment Repair (CTSCA-ER), and Network Repair (CTSCA-NR). Individuals who earn all three certifications receive a full “Automation Master” recognition award.

Skill Boss Logistics was developed to teach and assess hands-on 100 skills required by today’s technicians in supply chain automation, including equipment maintenance and equipment repair. The bench-sized automated sortation system showcases the distribution of packages to three destinations and includes an easy-to-use, hands-on training manual. The compact design allows the system to fit easily in any classroom or training facility. It's transportable for use in multiple locations.

MSSC’s CT-SCA Certifications

This system is used by the Manufacturing Skill Standards Council (MSSC) for its Certified Technician – Supply Chain Automations certifications. The Skill Boss Logistics, designed to meet MSSC standards, is a hands-on skill assessment system that integrates seamlessly into any logistics program. MSSC’s CT-SCA program provides proof of an individual's ability to perform a wide range of hands-on technical skills in electronic, electrical, and mechanical systems.

The CT-SCA program is an industry-led standards-based training, assessment, and certification system focused on the core skills and knowledge needed by the nation’s logistics workforce. Using the 95-MSB3, students will study vertical package sorting, conveyor materiel handling, jam sensing, and product gap optimization.

Real Industrial Quality Components

Like all of Amatrol’s training systems, the Skill Boss Logistics utilizes real-world industrial components that students are sure to encounter on the job. The system includes a variety of supply chain automation components, including multiple types of conveyors, electro-pneumatic sorters, a vacuum, and much more. These components, which range from AC/DC Electric Motors to a Variable Speed Distribution Conveyor, will not only give students a familiarity boost in the field but helps them display their expertise in this space with highly effective hands-on tools.

Comprehensive Online Curriculum

While the Skill Boss Logistics system will provide hands-on skill-building for students, Amatrol’s logistics training doesn’t stop there. Like all of Amatrol’s learning systems, the 95-MSB3 includes a world-class eLearning curriculum that features videos, audio voiceovers, 3D animations, and interactive quizzes and activities. The interactive multimedia curriculum focuses on a variety of industry-needed skill areas, including package data tracking and control, package re-circulation, and 2D barcode tracking.

Skill Boss Logistics Evaluates 100 Essential Hands-On Skills

Equipment MaintenanceSkill Boss Logistics Training and Assessment Device

- Preventative Maintenance

- Equipment Adjustment

- Measurement

- Hand Tools

- System Monitoring & Operation

- Equipment Repair

Pneumatics

- Mechanics

- Electrical Installation

- System Troubleshooting

- Print Reading

- Network Repair

Programmable Logic Controllers (PLCs)

- Variable Frequency Drives (VFDs)

- Barcode Readers

- Ethernet Network Test and Operation

- Electronic Installation

- System Troubleshooting

Take Troubleshooting to Next Level with Amatrol’s Exclusive Computer-Based Fault Insertion Program

FaultPro Technical Training Skills AssessmentFaultPro, included with the Skill Boss Logistics, allows users to insert electronic faults for realistic troubleshooting of situations they will encounter on the job. The faults used by FaultPro are electronically-controlled circuits located in the hardware of Amatrol’s troubleshooting training systems. The FaultPro software safely inserts over 45 real-world faults to enable training and assessment of troubleshooting skills. FaultPro teaches troubleshooting skills and provides data reports for assessment and improvement.