Level and Flow Process Control Troubleshooting Learning System

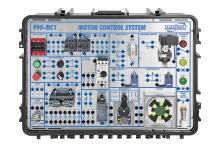

Amatrol’s Level and Flow Process Control Troubleshooting Learning System (T5552F) covers calibration, installation, operation, and troubleshooting for flow and liquid level process control systems and components. The process control training system uses industry-standard components mounted and plumbed in a closed-loop circuit to provide learners with the opportunity to practice manual and automatic control of a process instrumentation system by controlling the water flow rate between two tanks or the liquid level in one tank.

Amatrol’s Process Control Troubleshooting Training System uses FaultPro, the industry’s only electronic troubleshooting system, to offer hands-on troubleshooting skills like in-circuit component testing methods and universal digital controller troubleshooting. This process control training system includes the industry’s best hands-on process control troubleshooting training, covering thirty-six (36) electrical faults, six (6) mechanical faults, PID controller programming errors, flow transmitter programming errors, and I/P converter calibration errors.

Major topics include: testing methods for flow valves, circulation pumps, pilot lights, process meters, and PID controllers; how to use a voltage tester; how to troubleshoot process instrumentation switches and relays; how to troubleshoot process sequences; hands-on in-circuit component testing; and how to tests and analyze process control circuit signals. Other topics include: troubleshooting flowcharts and tables, using status and diagnostic indicators, and using wiring diagrams and P&IDs in troubleshooting.

Troubleshooting on the Process Control Training system is provided via FaultPro, Amatrol’s world-class electronic fault insertion system, which allows instructors to set and tailor faults for learners in order to turn their weaknesses into strengths.

Industrial-Grade Process Control Components

Ideal for Hands-On Learning

The Process Instrumentation Training system includes industrial-grade components like a centrifugal pump, electric motor, regulators, gauges, and three different controllers on the control panel: relay control for automatic on/off liquid level control, the PID controller for variable electronic control of either liquid level or flow, and PLC control for both on/off and PID control of the system.

This process control troubleshooting training system is extensively instrumented, which enables learners to observe the system’s operation, understand the effects of external disturbances, and how their hands-on adjustments affect the process.

In-Depth Curriculum

With Extensive System Control Function and Troubleshooting Knowledge

- Level / Control Process Control Multimedia Courseware (MB270)

- Level / Control Process Control Troubleshooting Multimedia Courseware (M33306)

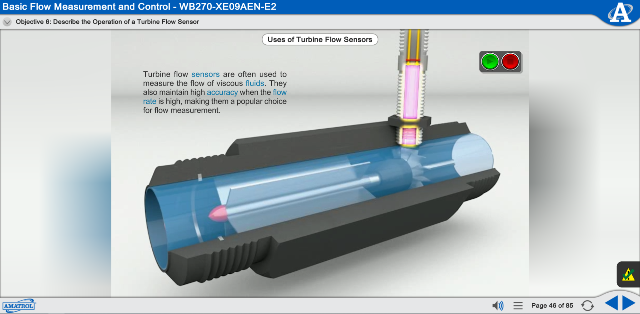

The interactive multimedia process control training course covers process control instrumentation, industrial safety rules, instrument tags, piping and instrumentation diagrams, and level measurement, then moves into system control functions such as liquid level control, automatic control methods, basic flow measurement and control, and control loop performance. The curriculum concludes with extensive component and system-level troubleshooting training.

This level and flow curriculum is presented in a stunning interactive multimedia format. This multimedia includes beautiful 3D graphics and videos, voiceovers of all text, and interactive quizzes and activities.

Student Reference Guide

A sample copy of the Level and Flow Process Control Troubleshooting Student Reference Guide is also included with the system for your evaluation. Sourced from the system’s multimedia curriculum, the Student Reference Guide takes the entire series’ technical content contained in the learning objectives and combines them into one perfectly bound book. Student Reference Guides supplement this course by providing a condensed, inexpensive reference tool that learners will find invaluable once they finish their training making it the perfect course takeaway.

Key Features

- Covers the calibration, adjustment, installation, operation, and troubleshooting of two of the most common types of process control systems, flow and liquid level

- Includes the industry’s best hands-on process control troubleshooting, covering 36 electrical faults, 6 mechanical faults, PID controller programming errors, flow transmitter programming errors, and I/P converter calibration errors

- Includes industrial-grade components like a centrifugal pump, electric motor, regulators, gauges, as well as three types of controllers on its control panel

Learning Topics

- Component Level Troubleshooting

- System Level Troubleshooting

- In-Circuit Component Testing Methods

- Out-of-Circuit Component Testing Methods

- Input & Output Troubleshooting

- Operation of a Loop Calibrator

- PID Controller Troubleshooting

- Universal Digital Controller Troubleshooting

- Process Control Concepts

- Piping and Instrumentation Diagrams

- Final Control Elements

- Level Measurement and Control

- Methods of Automatic Control

- Basic Flow Measurement and Control

- Control Loop Performance

Additional Requirements

- Electricity (120 VAC/60 Hz/1 phase)

- Computer: See requirements

- PID Controller Module – Single Loop (T5554-C1-A)

- Water

More Information

Also available without Fault Troubleshooting (T5552)

Visit Amatrol for more information.