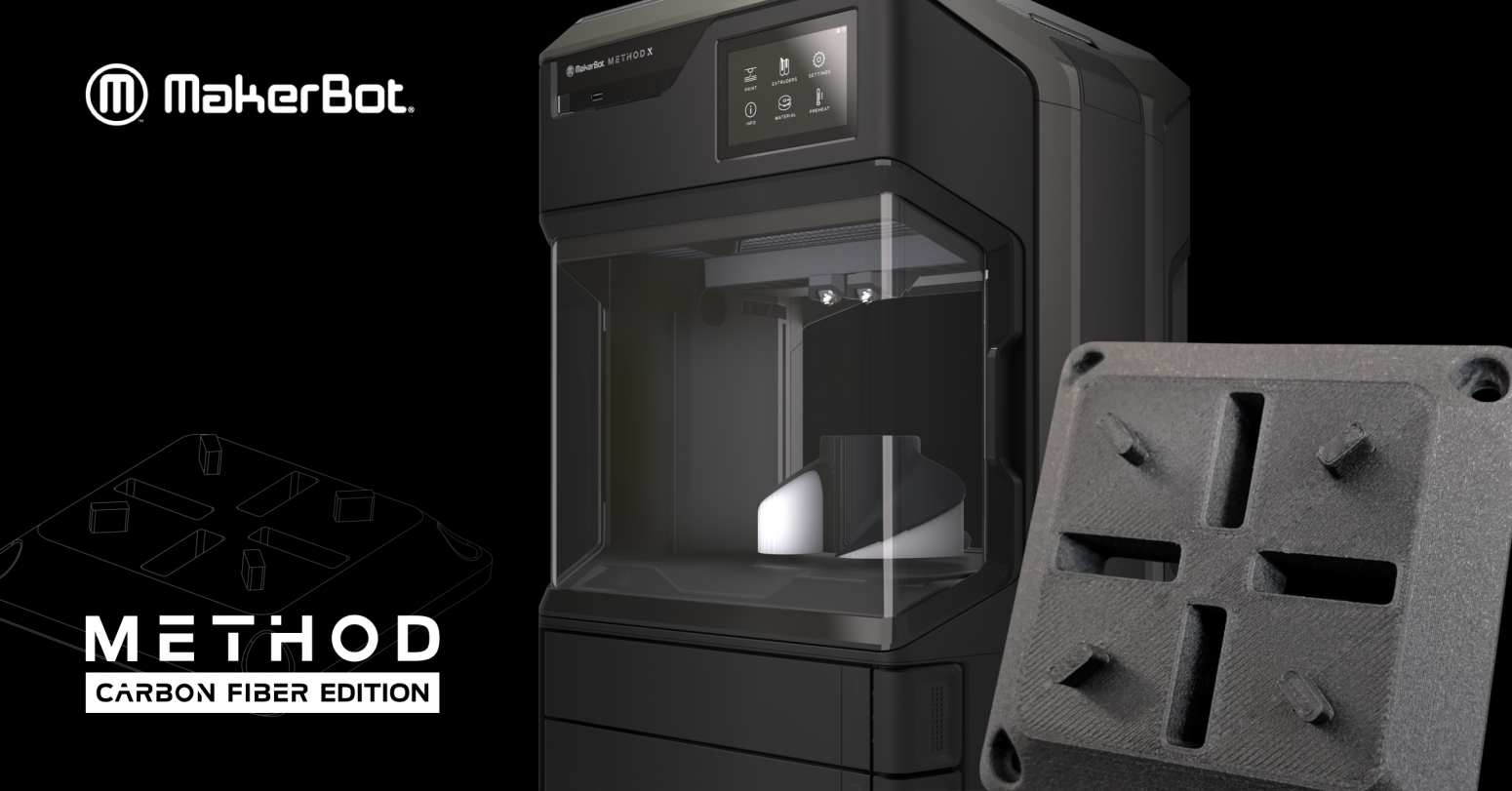

MakerBot Method Carbon Fiber

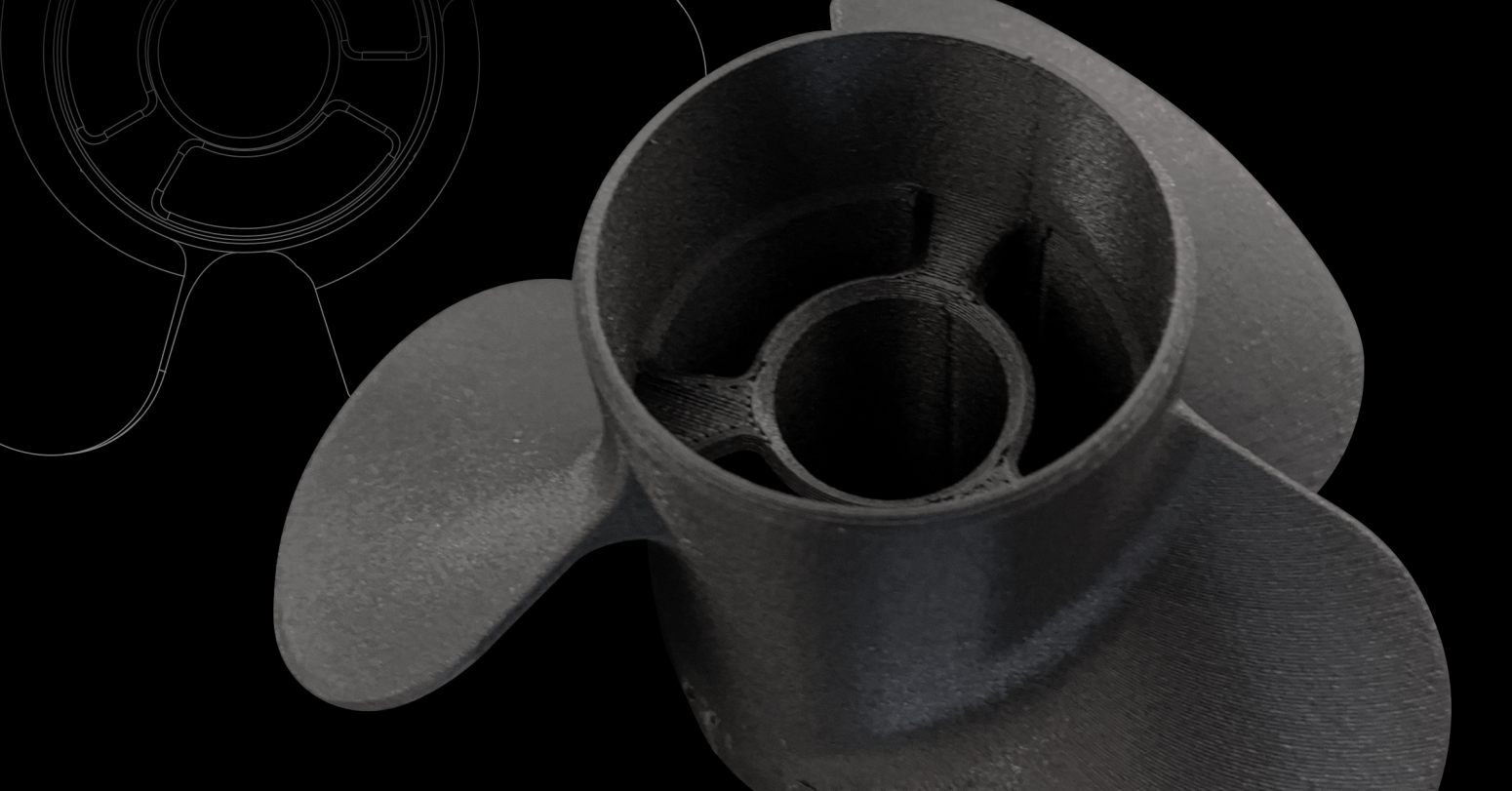

Replace metal parts with 3D printed Carbon Fiber on a MakerBot Method

Print carbon fiber reinforced nylon and other engineering-grade composite parts with three-dimensional strength and accuracy like never before on METHOD’s unique industrial desktop platform.

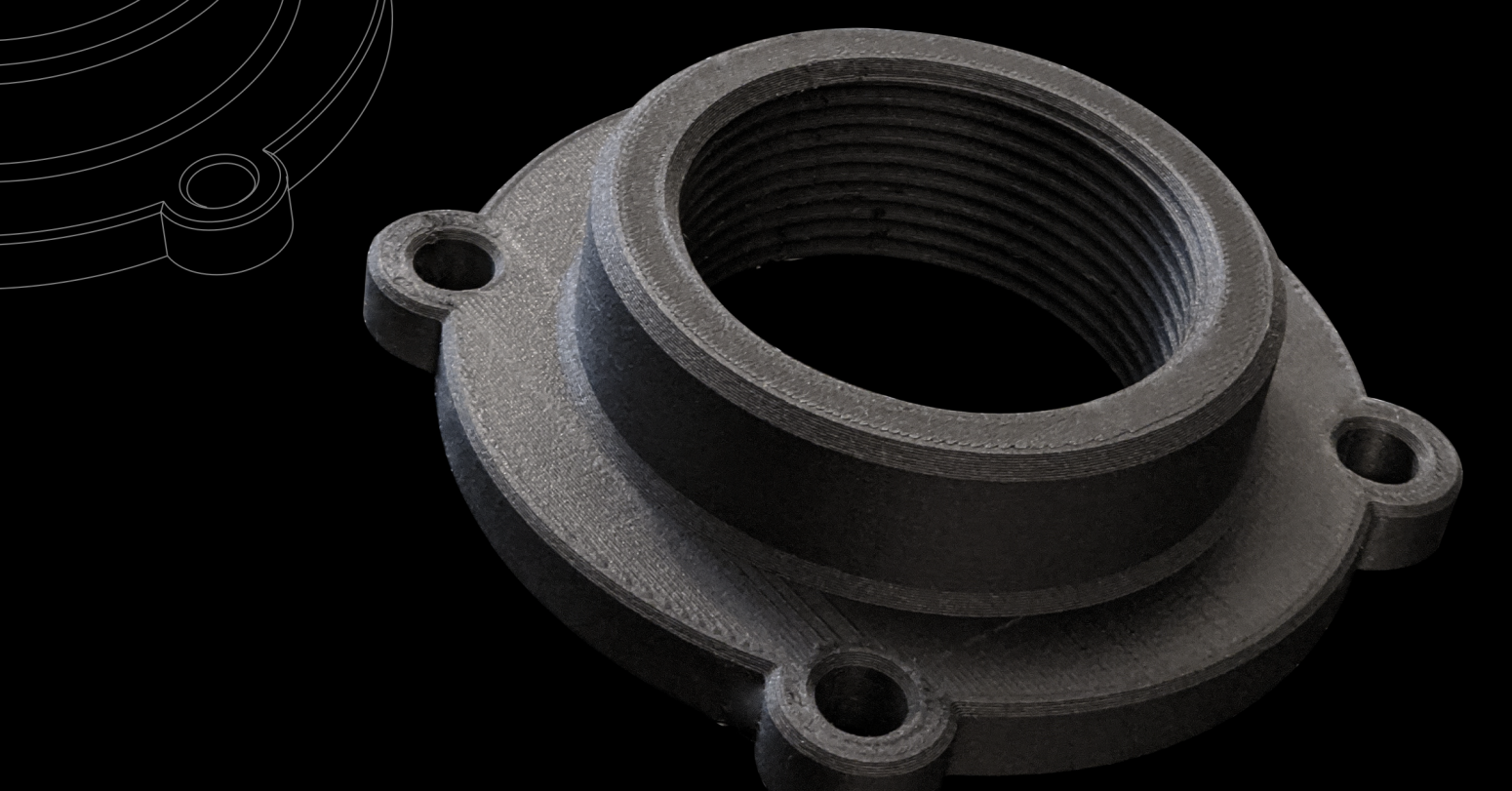

Strong, Heat-Resistand Metal Replacement Parts

Carbon fiber reinforced nylon is optimized for high strength, stiffness, and heat resistance making it ideal for structural applications and metal replacements.

- Excellent strength to weight ratio - 110 MPa TS - for lightweighting applications such as robotic end effectors

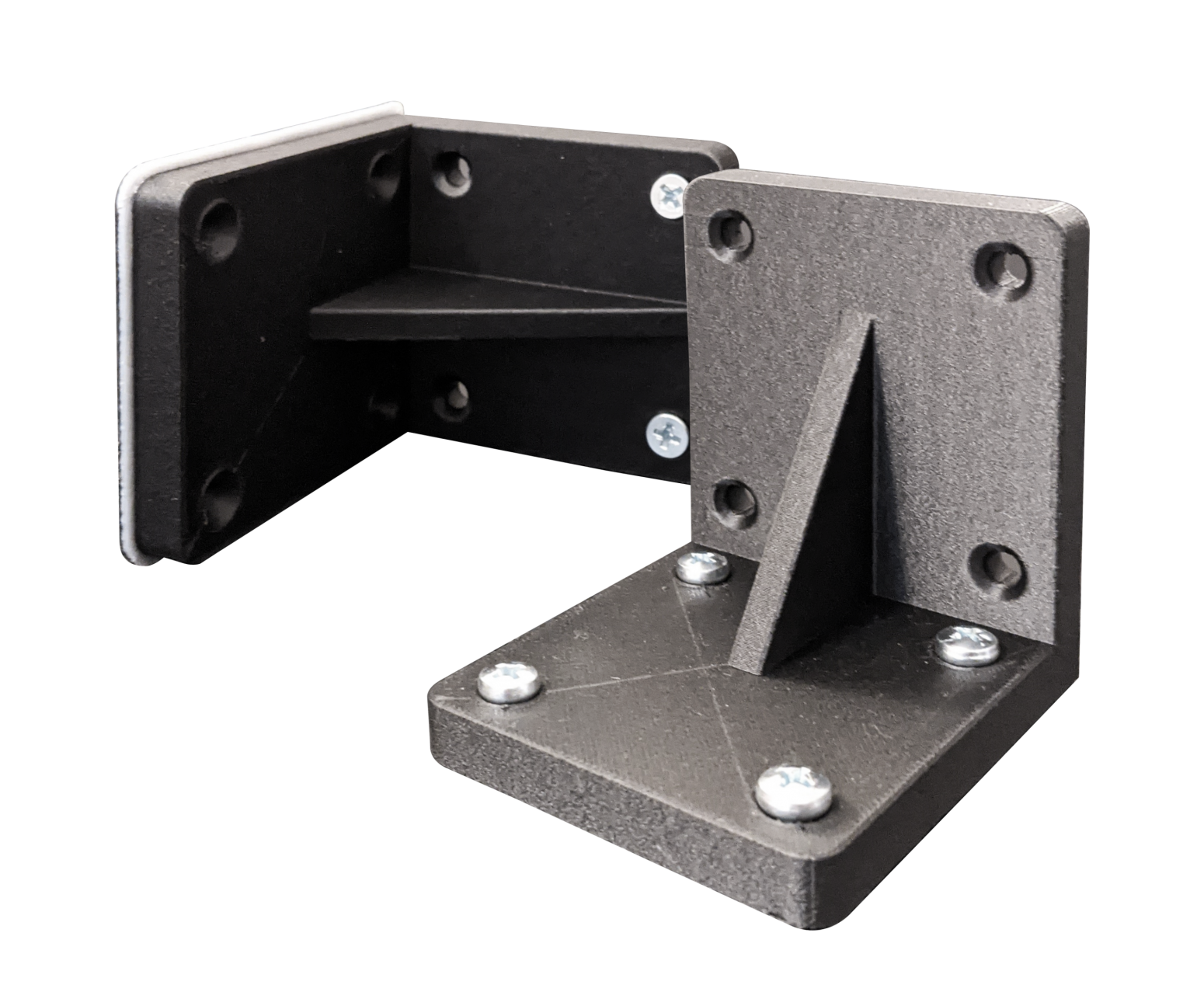

- Engineering-grade stiffness - 7600 MPa Tensile Modulus - for structural applications such as vehicular brackets and inspection gauges

- High heat resistance under load - 184°C HDT - for optimal under-hood and tooling applications

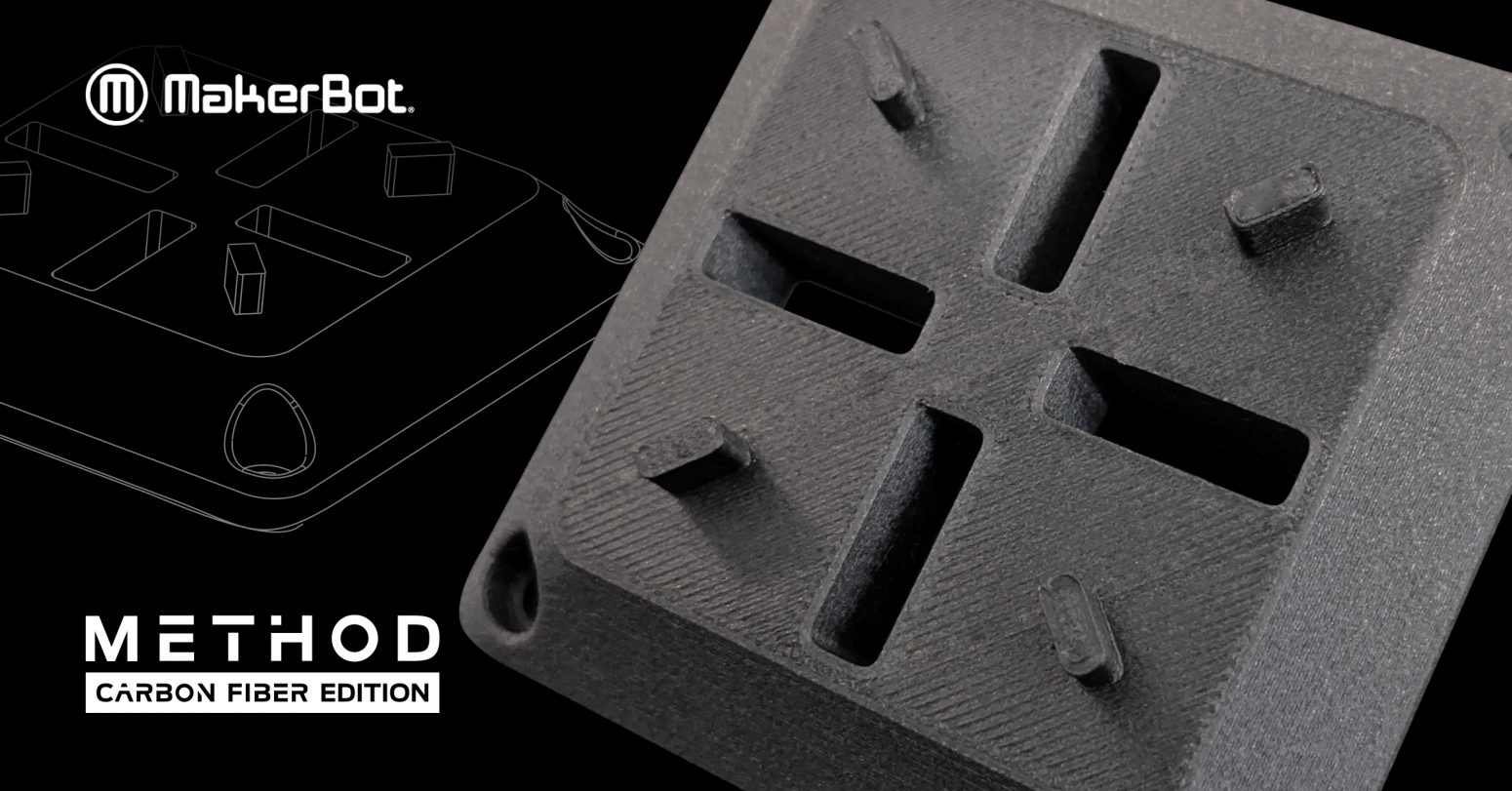

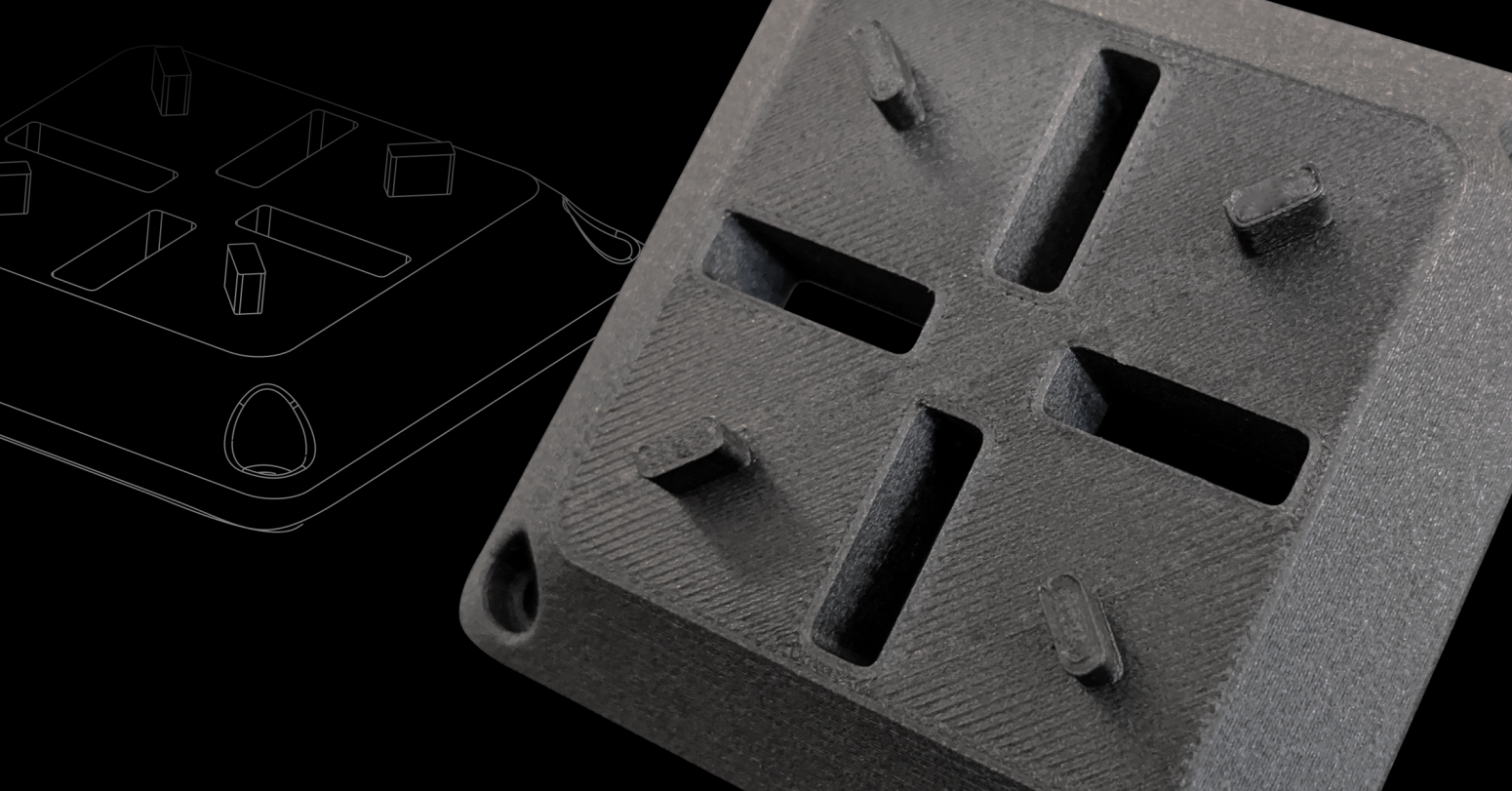

Superior Nylon Carbon Fiber Parts

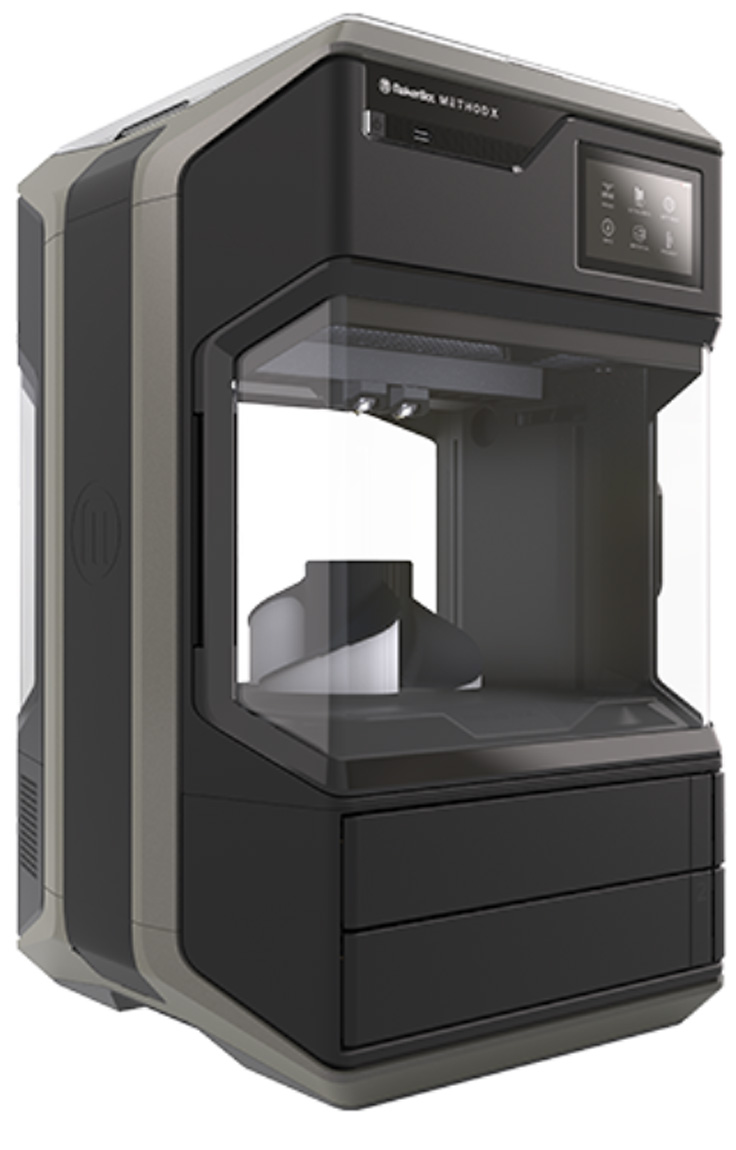

METHOD’s unique industrial feature set produces carbon fiber parts with superior three-dimensional strength and accuracy.

- METHOD’s Heated Chamber delivers parts that are strong and accurate.

- Outstanding surface finish that hides layer lines thanks to METHOD’s Ultra-Rigid Metal Frame.

- Print the most complex geometries including internal cavities with soluble support, or use breakaway support for faster print times.

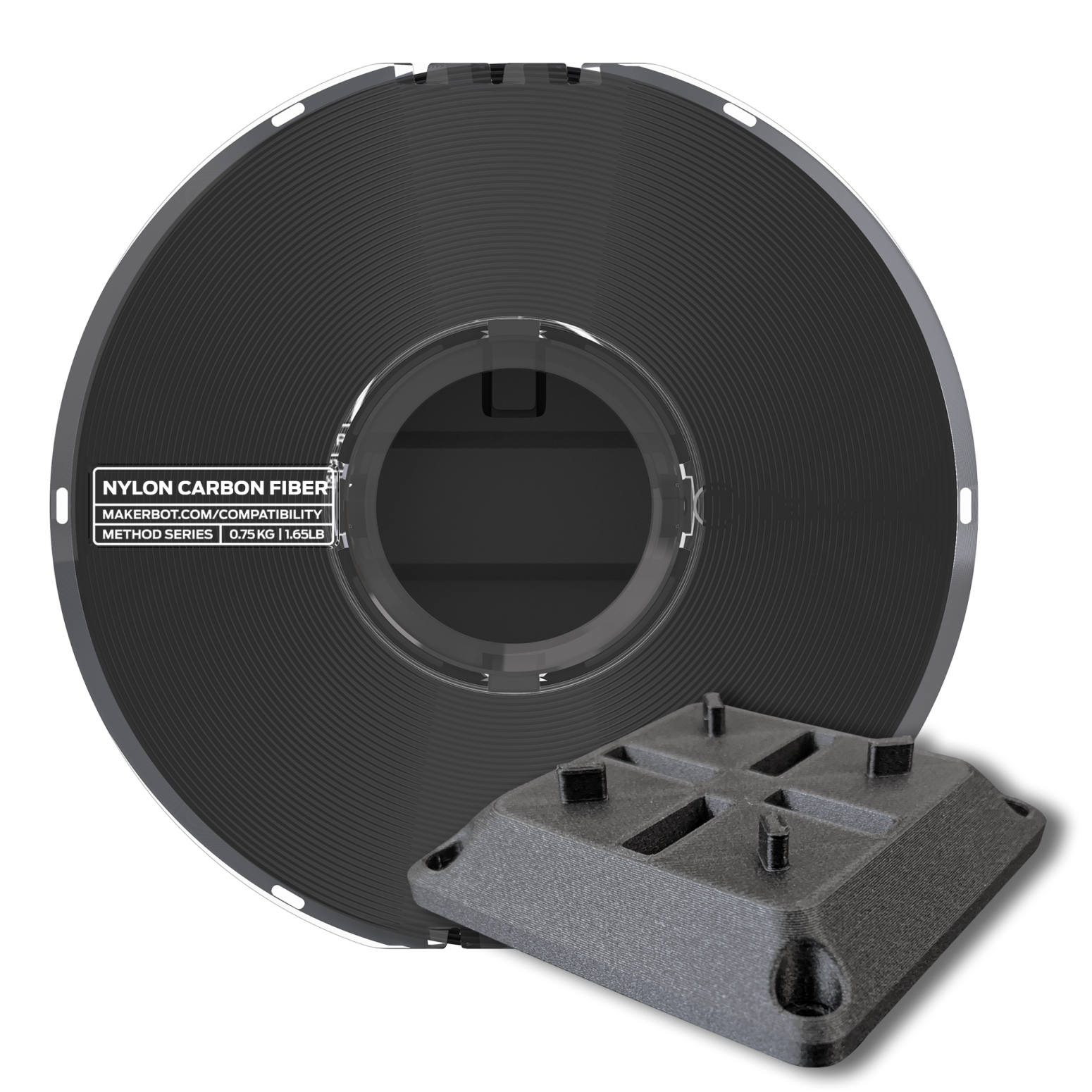

- METHOD’s sealed filament bays help keep the material dry, resulting in better print quality and reliability, and METHOD’s pre-print spool drying feature allows for the recovery of oversaturated filament.

Features

- Circulating Heated Chamber

- Includes MakerBot Composite and Support Performance Extruders

- Dry-Sealed Material Bays

- Pre-Print Material Drying

- Post-Wash Part Annealing

- Ultra-Rigid Metal Frame

- MakerBot Cloud Connected

More Information

Manufacturer: