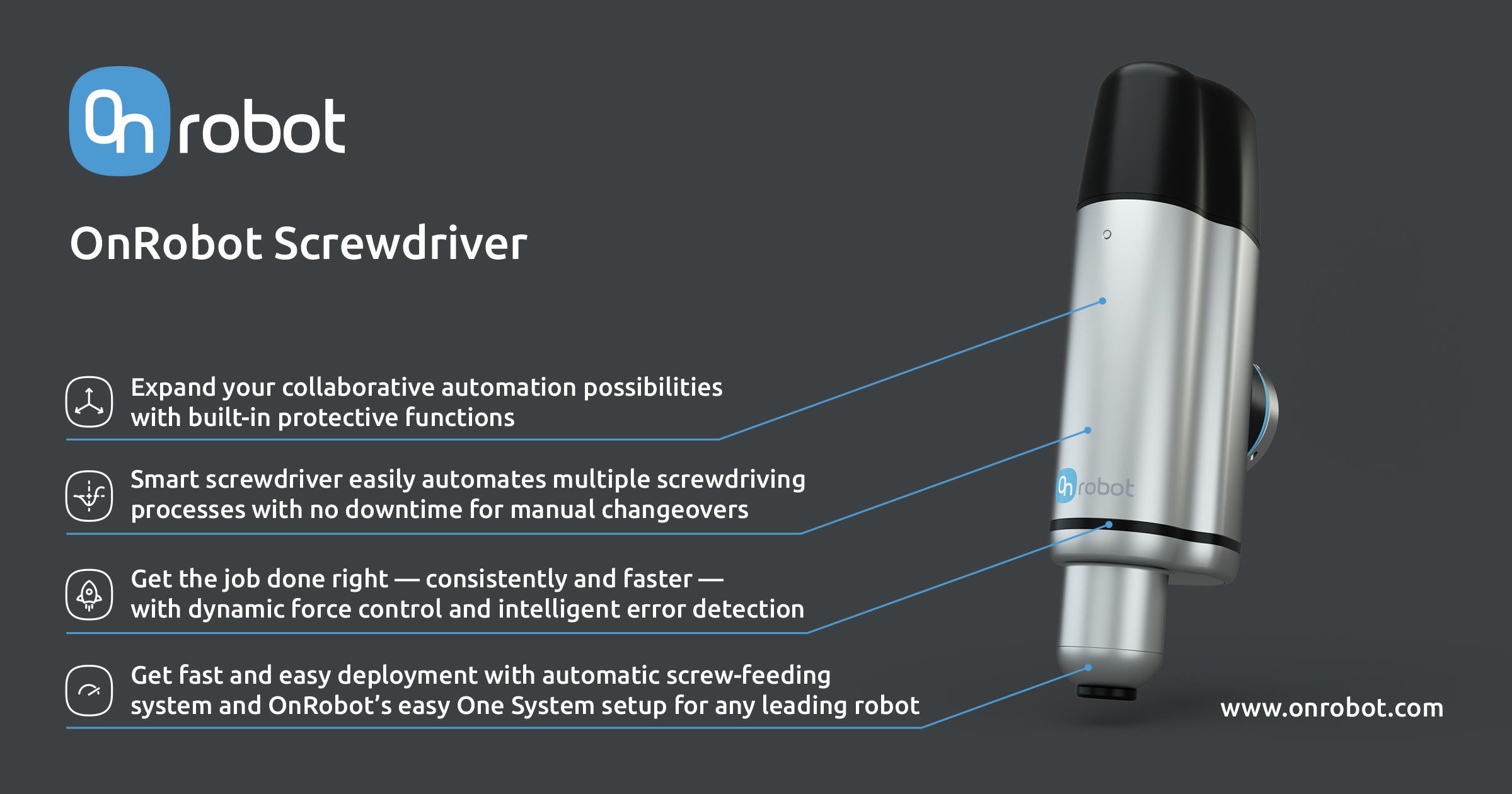

OnRobot Screwdriver

- Easy out-of-the-box setup, programming, and deployment on any leading robot

- Highly versatile and flexible, with fast changeovers for a wide range of screw sizes and lengths

- Precise torque control and intelligent error detection ensure quality and consistency

- Embedded axis motion control simplifies programming, speeds setup, and improves quality

Why OnRobot Screwdriver?

You can easily automate assembly processes with the new intelligent OnRobot Screwdriver for light industrial and collaborative robots. Intelligent error detection and multiple screw size handling will ensure consistent results and reduce your cycle time dramatically.

QUALITY AND CONSISTENCY

Precise force control and intelligent error detection.

HIGHER PRODUCTIVITY

HIGHER PRODUCTIVITY

Automate multiple screwdriving processes with a fast, out-of-the-box setup and deployment.

TIME SAVING

Fast and easy deployment with One System setup.

Advantages and Features

Automated screwdriving to boost productivity and quality has never been easier, smarter, or more cost-effective. The OnRobot intelligent Screwdriver speeds setup and programming, with everything you need right out of the box. Simply mount the Screwdriver on any leading robot arm and install the appropriate bit, then enter screw length and torque directly into the robot’s user interface. Precise torque control and embedded axis eliminate the time and cost for additional integration and ensures consistent, accurate screw insertion. Changeovers to a different screw type or size take just minutes, reducing downtime and boosting ROI.

The OnRobot Screwdriver and available screw feeders handle a wide range of screw sizes from M1.6 to M6 and up to 50mm long. Precise torque control ranges from 0.15 Nm to 5 Nm. More versatile and intelligent than traditional tools, the OnRobot Screwdriver can detect if the screw is picked, is the correct length or been properly inserted during the tightening process.

The OnRobot Screwdriver includes protective functions that make it appropriate for collaborative applications for screws up to 35mm long, which are fully retracted into the Screwdriver while in motion. Safety stop is automatically activated if a screw is exposed to excessive force along its axis, with alert lighting to indicate the issue.

FAST, EASY SETUP AND CHANGEOVERS

Complete screwdriving solution includes screw feeder and the easy One System setup for any leading robot brand.

PRECISE TORQUE CONTROL

Torque control ranges from 0.15 Nm to 5 Nm for consistent and accurate screwdriving.

EMBEDDED AXIS

Screws are retracted inside the tool and driven automatically once the robot arm moves into position, which reduces robot arm movement and simplified programming.

WIDE RANGE OF SCREW SIZES AND LENGHTS

Handles screw sizes from M1.6 to M6 up to 50mm long. Change-overs to a different screw type or size take just minutes, reducing downtime and boosting ROI.

BUILT-IN PROTECTION FUNCTIONS

Screws up to 30mm long are withdrawn inside the screwdriver when moving. Safety stop automatically activates if a screw is exposed to excessive force.

ESD CERTIFIED

Suited for all assembly environments, including electronics.

Applications

Assembly

Assembly

Ideal for automated assembly processes with consistent, high-output results and protective functions for a safer collaborative application.

Accessories

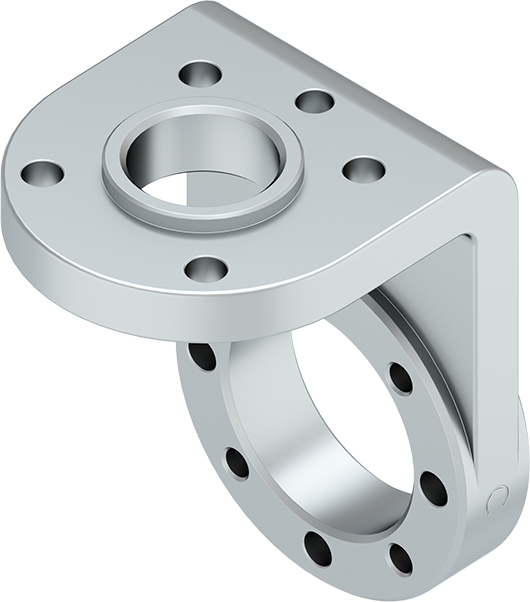

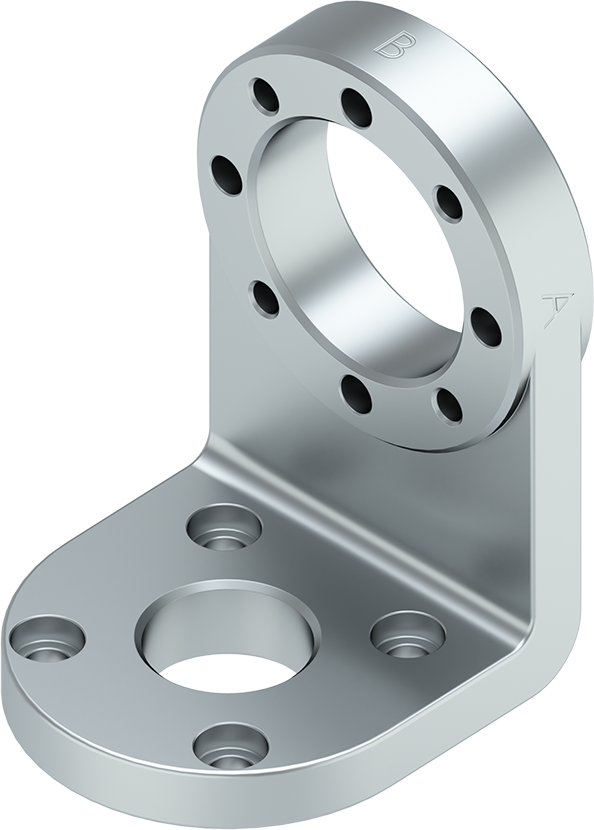

Angle bracket - 90 deg

Enables the user to attach tools at a 90 degree angle to the robot flange. This improves the tool's ability to fit into tight spaces and lowers the risk of the robot arm going into singularity.

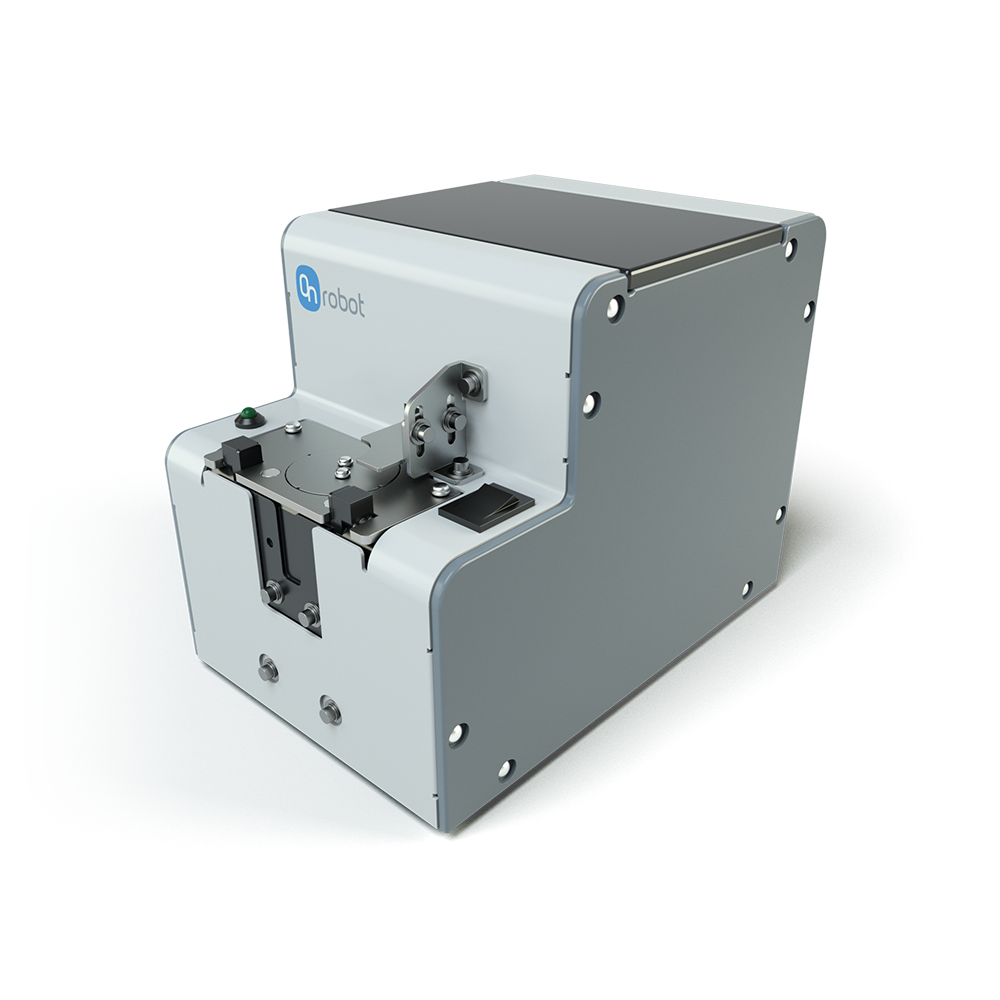

Screwdriver Kit

US Standard screw bit system to support many screw type and sizesranging from 1# to 1/4. Metric Kit also available.

Screwfeeder M1.6 to M2-M6

Automatic screw feeding system for screw sizes ranging from M1.6 to M6 - 1# to 1/4.