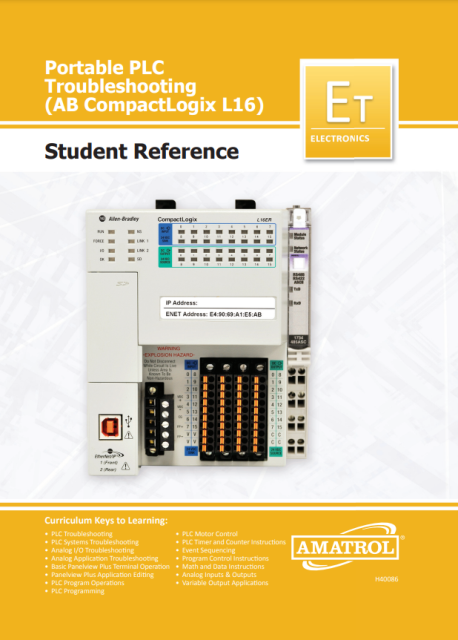

Portable PLC Troubleshooting Training

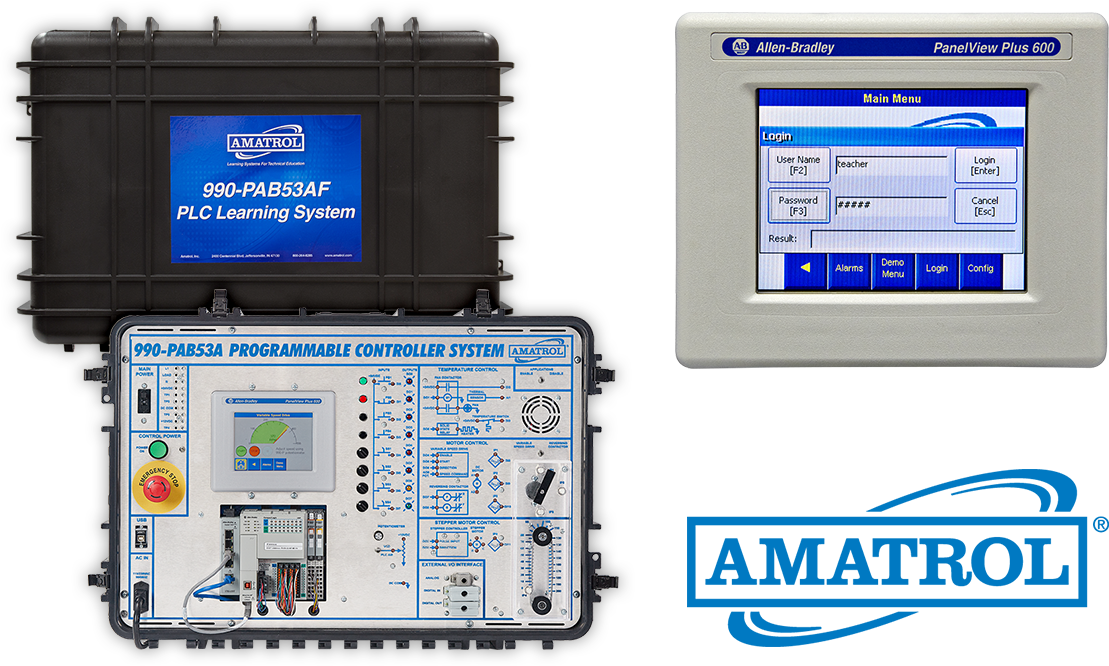

Amatrol’s Portable PLC Troubleshooting Learning System - AB CompactLogix L16 (990-PAB53AF) teaches programmable logic controller (PLC) programming, operation, and applications used throughout industry. The system also utilizes FaultPro, the industry’s premier computer-based fault insertion system. FaultPro enables learners to develop key PLC troubleshooting skills, such as PLC input and output testing, software testing, and application troubleshooting.

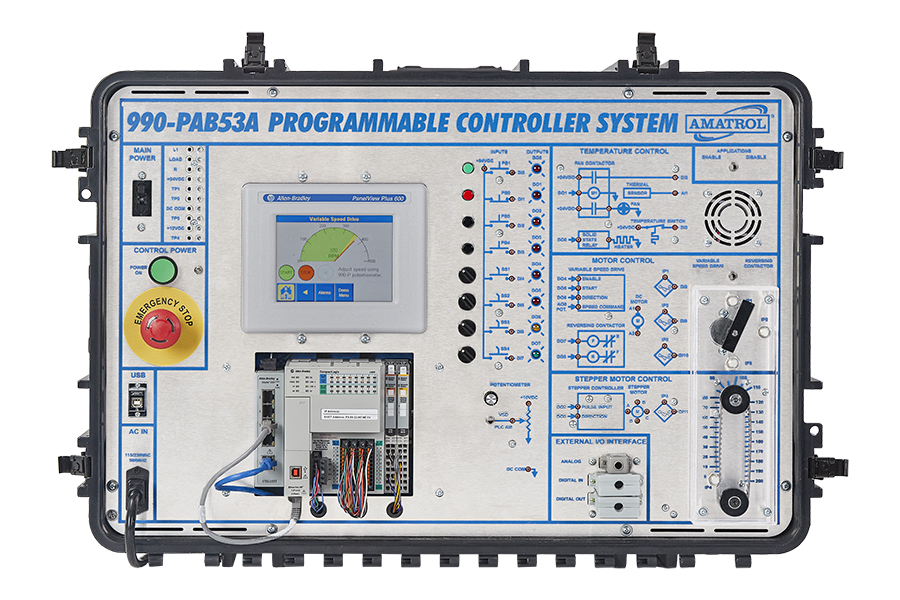

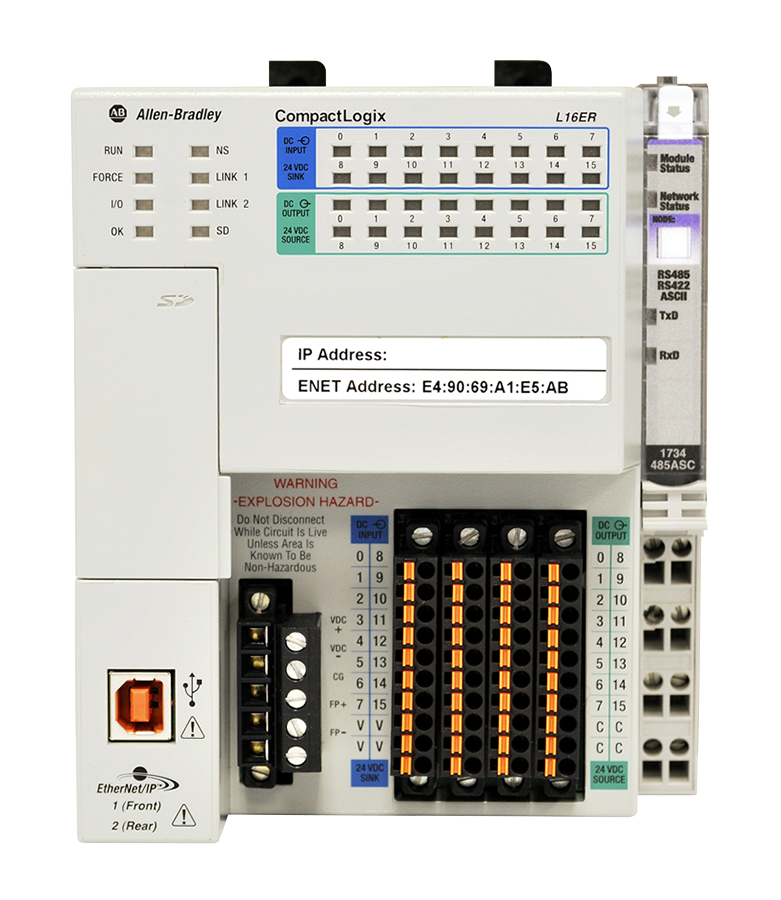

This portable system provides hands-on experience with real-world components, including the powerful Allen-Bradley L16 CompactLogix 5300 PLC, a PanelView Plus terminal, an Ethernet Switch, an I/O Simulator, five application circuits, and a master control relay circuit. Learners will study industry-relevant applications and troubleshooting skills that will build a strong foundation for a successful career in various industries.

Teach Skills Hands-On

Cutting-Edge PLC Programming & Troubleshooting

The 990-PAB53AF with FaultPro includes a variety of electronic faults that present realistic situations that technicians encounter on the job. This allows learners to develop important PLC troubleshooting skills, like PLC input and output testing, software testing, and application troubleshooting. Learners will practice skills, such as using a six-step sequence to troubleshoot a PLC system, troubleshooting a PLC routine that performs on/off control using an analog input, and testing a PLC-controlled PWM output device. FaultPro’s computer-based faults automatically track progress, enabling learners to gain troubleshooting skills in a self-paced environment that ensures faults are inserted safely, protecting both learners and equipment.

Rich Applications: Basic through Advanced

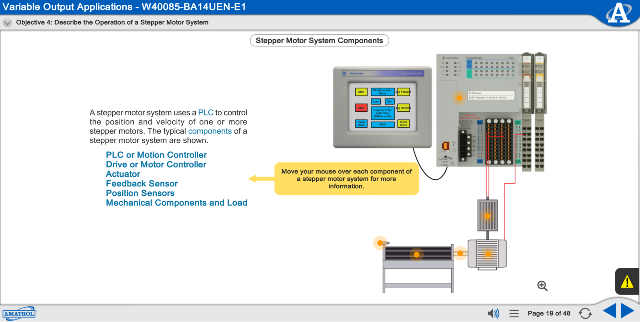

In addition to troubleshooting skills, the 990-PAB53AF includes application circuits and components for thermostatic temperature control, analog temperature control, reversing constant-speed motor control, variable speed motor control with feedback, and stepper motor homing and commissioning. These circuits include basic and advanced applications starting with discrete I/O projects and extending to projects involving analog I/O. These applications enhance learners' experience because they can see how a program controls real systems.

Interactive eLearning

In-Depth PLC Programming & Troubleshooting Curriculum

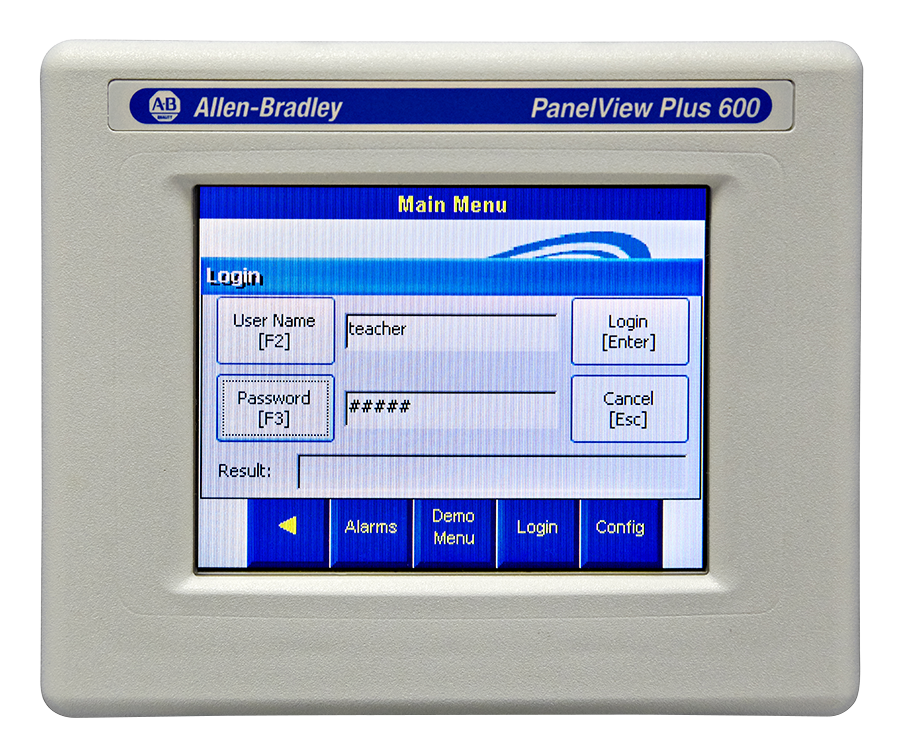

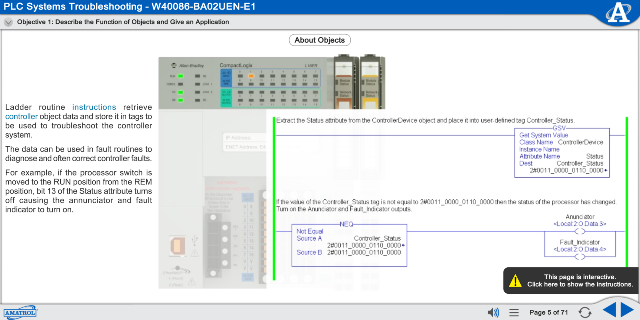

Amatrol's portable PLC troubleshooting training system features an interactive eLearning curriculum that integrates various types of learning methods to create an engaging, effective learning experience. Amatrol’s multimedia eLearning curriculum includes text with voiceovers, videos, 3D animations, pictures, and interactive activities, quizzes, and self-reviews. Specific PLC programming and troubleshooting topics covered include PLC programming; PLC motor control; event sequencing; PanelView Plus application editing; analog inputs and outputs; PLC systems troubleshooting; and analog I/O and applications troubleshooting. Within these topics, learners will study objectives like entering and running a basic routine using Studio 5000 software; designing a continuous-cycle reciprocating actuator PLC project to control a traverse axis; entering a PLC program to jog and home a stepper motor system; and troubleshooting a continuous cycle reciprocating motor PLC project.

Free Learning Management System (LMS)

Amatrol eLearning is easy-to-use for both students and instructors. Its web-based interface is simple to navigate and available on any WebGL-compatible Internet browser. Instructors love Amatrol eLearning for its simple, yet sophisticated Learning Management System (LMS). The LMS allows instructors to create custom courses, monitor student participation, track course progress, assess knowledge levels before a course, and test knowledge levels after completion. Learners appreciate they can start and stop as needed, moving through each Amatrol course at their own pace. If a self-review reveals that they didn’t understand a particular topic as well as they thought they did, they can revisit it before moving on.

More Information

Learning Topics

- Programmable Logic Controllers

- PLC Systems Troubleshooting

- Analog I/O & Application Troubleshooting

- PanelView Plus Terminal Operation & Application Editing

- PLC Programming

- PLC Motor Control

- PLC Timer and Counter Instructions

- Event Sequencing

- Program Control Instructions

- Math and Data Move Instructions

- Analog Inputs & Outputs

Requires

- RS Logix 5000 PLC Programming Software (82-8RSMI) or RS Logix 5000 Mini PLC Programming Software (82-8RSM) (Optional: RS Logix 5000 PLC Programming Software for Education (82-800 or 82-800-I))

- FactoryTalk View ME Programming Software (82-711)

- Router (if using more than one 990-PAB53AF on the same network)

- Computer (see Computer Requirements)

Utilities

- Electricity (100-240V/50-60Hz/1ph)

Options

- Mobile Technology Workstation (82-610)