Vibration Analysis Training System Plus

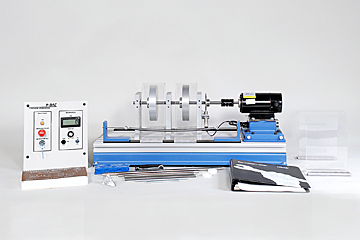

DAC Worldwide’s Vibration Analysis Training System Plus (203-PAC) is a heavy-duty learning package that allows for in-depth training in vibration analysis, using a vibration meter, gear/belt drives, and bearing faults. Through the use of internally gauged studs and associated instrumentation, the Vibration Analysis Training System demonstrates the cause and effects of vibration in industrial rotating machinery. The package includes a Vibration Analysis Demonstrator (203), a Basic Vibration Meter (203-003), a Gear/Belt Drive Accessory (203-002), and a Bearing Fault Kit (203-010).

Using the Vibration Analysis Training System, learners will gain experience on a versatile, precision-machined device that allows for isolation of individual, vibration-causing variables in order to demonstrate their individual signatures. Learners will use the demonstrator’s industrial-grade components to study topics such as effects of frequency/displacement, proper pick-up mounting, correcting vibrations caused by imbalance and misalignment, and more. Not only do the components provide durability to stand up to frequent use, but they also aide learners in becoming better prepared for the tasks they will encounter on the job.

This training package includes an assortment of rotors, gears, and bearings, which allow for a variety of hands-on exercises. The trainer also provides skill-building for industry-relevant tasks, like single-phase balancing, performing the four-run method, and how to align for center-to-center variation.

Practice Hands-On Mechanical Skills for Various Applications

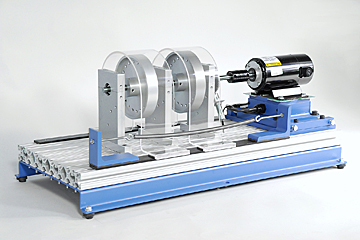

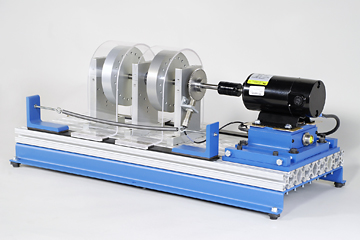

Working as the center piece of this training package, DAC Worldwide’s Vibration Analysis Training System features a heavy-duty steel sub-based with adjustable feet. It includes a 1/3 HP three-phase AC Motor, three (3) precision-machined split pillow blocks, two (2) 6-inch rotors, three (3) ½-inch diameter shafts, and provisions for creating rotor imbalance using set screws/washers. It also comes with an Allen wrench and combination wrench set, a weight/washer set, and a resonance demonstration kit.

The Basic Vibration Meter (203-003) is an industrial-duty, handheld diagnostic tool that represents an important troubleshooting tool for the working maintenance department. The device has three measurement ranges and three modes of measurement, and is an ideal aide for teaching the principles of severity, while allowing use in a wide range of amplitudes.

DAC Worldwide’s Gear/Belt Drive Accessory (203-002) helps learners detect belt and gear faults, which are regularly encountered by maintenance personnel when performing preventive and predictive maintenance on industrial rotating equipment. To round out the package, the Bearing Fault Kit (203-010) educates learners on a variety of industrial-grade ball bearings with removable shields.

Expand Training with Additional Mechanical Options

The Vibration Analysis Training System Plus is only one of DAC Worldwide’s Vibration Analysis mechanical training systems, which also includes an Extended Vibration Analysis Demonstrator (203E). Other mechanical demonstrators include the Fan Balancing Demonstrator (202-000), the Reciprocating Compressor Dissectible Trainer (211-000), Motorized Multi-Turn Valve Actuator Trainer (212-000), and many more!

Student Training Manual and Textbook

A copy of this course’s Student Training Manual and Textbook are included with the training system. Sourced from the Exercises and Learning Activities, the Student Training Manual takes the technical content contained in the learning objectives and combines it into one perfectly-bound book. The textbook, called IPT Rotating Equipment, presents clear objectives and performance standards for learners. If you would like to inquire about purchasing additional Student Training Manuals or Textbooks for your program, please contact your local DAC Worldwide Representative for more information.