RenAM 500 Ultra

The Renishaw RenAM 500 Ultra series stands as the pinnacle of the company's laser powder bed fusion (LPBF) systems, elevating metal additive manufacturing (AM) capabilities to new heights. Central to its prowess is Renishaw's revolutionary TEMPUS technology, boasting the potential to amplify the productivity of the RenAM 500 series by up to 100%. Despite these remarkable speed enhancements, the RenAM 500 Ultra maintains its hallmark of delivering top-tier part quality.

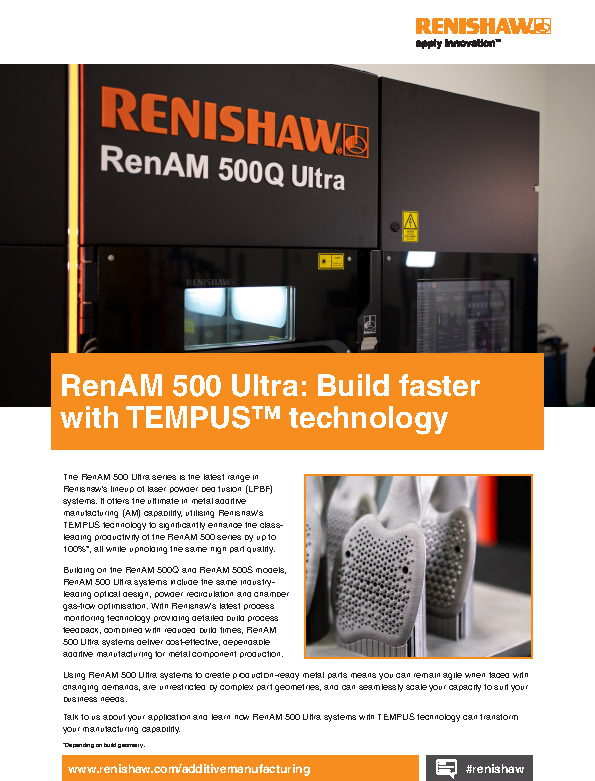

Expanding on the strengths of its predecessors, the RenAM 500Q and RenAM 500S models, the RenAM 500 Ultra retains industry-leading optical design, optimized powder recirculation, and chamber gas-flow features. Augmented by Renishaw's cutting-edge process monitoring technology, which furnishes intricate insights into the build process, these systems promise efficient, reliable, and cost-effective metal component production.

The RenAM 500 Ultra systems empower manufacturers by enabling adaptability to fluctuating demands, overcoming complex part geometries, and seamlessly adjusting capacity to match evolving business requirements. Prospective users are encouraged to engage with Renishaw to explore how the RenAM 500 Ultra, integrated with TEMPUS technology, can revolutionize their manufacturing capabilities, potentially doubling productivity, contingent upon the intricacies of the build geometry.

-

As the newest addition to Renishaw’s laser powder bed fusion (LPBF) systems, the RenAM 500 Ultra series represents the pinnacle of metal additive manufacturing (AM) technology. Powered by Renishaw’s groundbreaking TEMPUS technology, it remarkably elevates the already top-notch productivity of the RenAM 500, maintaining exceptional part quality.