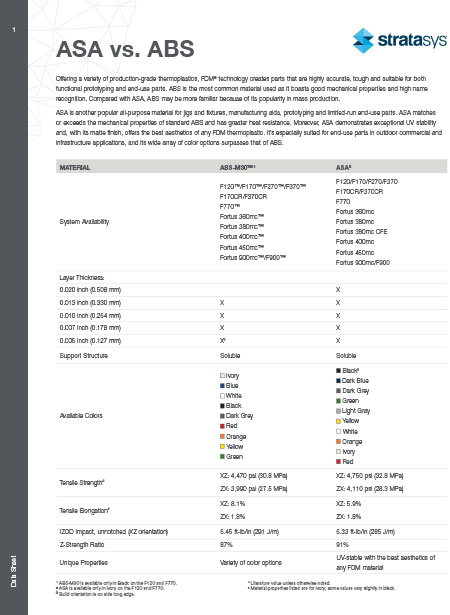

ASA vs ABS

Offering a variety of production-grade thermoplastics, FDM® technology creates parts that are highly accurate, tough, and suitable for both functional prototyping and end-use parts. ABS is the most common material used as it boasts good mechanical properties and high name recognition. Compared with ASA, ABS may be more familiar because of its popularity in mass production.

ASA is another popular all-purpose material for jigs and fixtures, manufacturing aids, prototyping and limited-run end-use parts. ASA matches or exceeds the mechanical properties of standard ABS and has greater heat resistance. Moreover, ASA demonstrates exceptional UV stability and, with its matte finish, offers the best aesthetics of any FDM thermoplastic. It’s especially suited for end-use parts in outdoor commercial and infrastructure applications, and its wide array of color options surpasses that of ABS.