Stacking Builds For Maximum Throughput on Origin One

One hundred parts produced within 24 hours on a single Origin One, at a fraction of the cost of traditional manufacturing.

Origin® One features several integrated cameras for computer vision and capturing temperature data in the IR range; additional sensors measure other environmental conditions during the print process.

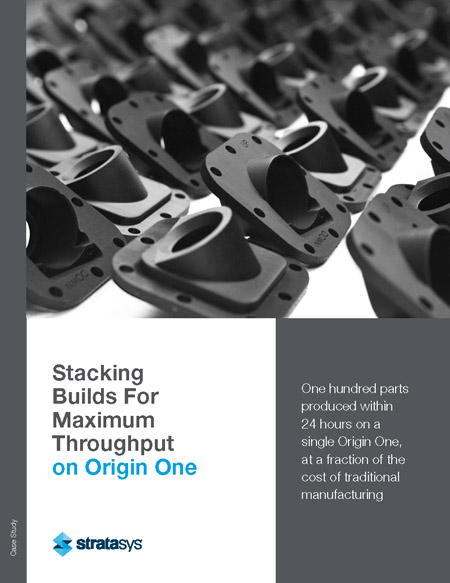

Senior mechanical design engineer Matt Miyamoto designed camera mounts for CNC machining out of black ABS plastic. A compound angle meant that the part could only be machined by a 5-axis CNC (or on a 3-axis CNC with multiple setups), which made the parts expensive to machine at low or high volumes. Matt turned to Origin’s solution to achieve the quality and throughput required.