PPSF/PPSU (polyphenylsulfone) has the greatest heat and chemical resistance of all FDM materials - ideal for aerospace, automotive, medical applications as well as for prototypes exposed to extreme conditions. PPSF/PPSU produced parts are mechanically superior and dimensionally accurate.

FDM Thermoplastics

Materials

-

-

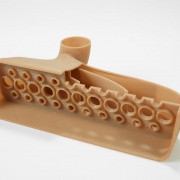

ST-130 (Sacrificial Tooling material) simplifies the production of hollow composite parts. Complex tools can be 3D printed and easily dissolved after curing, eliminating secondary processes like mold making, while accelerating your composite lay-up work.

-

ULTEM ™ 1010 resin offers the highest heat resistance, chemical resistance, and tensile strength of any FDM thermoplastic. The certified grade of this material is bio-compatible and approved for food contact with NSF 51 and ISO 10993/USP Class VI certifications. Ideal for automotive, aerospace, medical, and food production industries. Available in one color.

-

ULTEM ™ 9085 resin is a pioneering thermoplastic that is strong, lightweight and flame retardant (UL 94-V0 rated). The ULTEM ™ 9085 resin material opens up new opportunities for the direct additive construction of production-grade components. Commonly used in the automotive, aerospace, and military industries. Available in two colors.

-

Victrex AM™ 200 is a low-melt polyaryletherketone (LMPAEK) thermoplastic FDM material. Designed specifically for additive manufacturing, it offers the benefits of a polyaryletherketone (PAEK) material while addressing the challenges associated with 3D printing this family of polymers that includes PEEK and PEKK.

Pages

- « first

- ‹ previous

- 1

- 2

- 3