PPSF Finishing Techniques

PPSF (polyphenylsulfone) is a high-temperature, high-strength, and chemically resistant FDM material. While ideal for demanding applications, the durability and chemical resistance make finishing PPSF parts with sandpaper or solvents difficult and time-consuming.

When smooth surfaces are needed, hand sanding or milling are the two options most often used. Resistant to abrasion, PPSF makes hand sanding a laborious task that can consume hours. While a finishing pass with a CNC mill can make short work of surface smoothing, it negates many of the advantages of the FDM process. To prepare for machining, time is needed for CAM programming and machine set-ups. Machining also requires that an operator oversees the process.

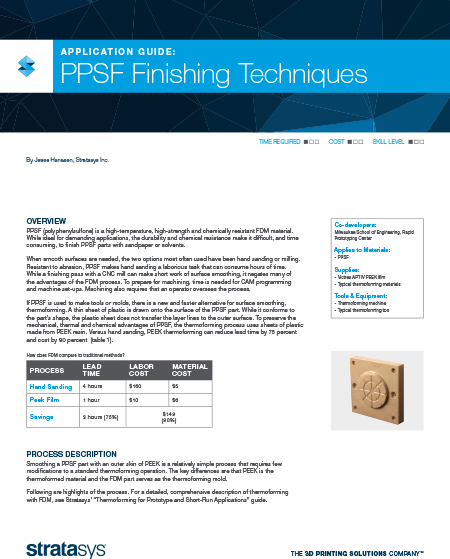

If PPSF is used to make tools or molds, there is a new and faster alternative for surface smoothing, thermoforming. A thin sheet of plastic is drawn onto the surface of the PPSF part. While it conforms to the part’s shape, the plastic sheet does not transfer the layer lines to the outer surface. To preserve the mechanical, thermal, and chemical advantages of PPSF, the thermoforming process uses sheets of plastic made from PEEK resin. Versus hand sanding, PEEK thermoforming can reduce lead time by 75 percent

and cost by 90 percent (table 1).