Bayport Training Systems

Bayport Technical’s trainers are hands-on training systems designed to give students real-world experience working on equipment they will encounter first-hand on the job. Each trainer has the look and feel of real industrial equipment, build with full-sized, industrial-quality components that will stand up to repeated use.

The trainers provide hands-on learning in a variety of industrial sectors. From a Custom Process Control trainer to a Standard Multiple Mechanic Trainer, Bayport Technical's trainers provide learners with realistic training that will help them perform their jobs more effectively in the field.

Bayport Technical offers trainers for a variety of industrial disciplines.

Trainers are available in the following Technical Topics:

- Electrical-Mechanical Maintenance

- Heat Transfer

- Instrumentation & Process Control

- Oil & Gas

- Unit Operations

Electrical-Mechanical Maintenance

Bayport's electro-mechanical maintenance training systems offer a variety of hands-on training solutions. Whether you need to teach basic electro-mechanical maintenance skills, shaft alignment, complete pump maintenance, gear, belt, and chain drive, or hands-on lock-out/tag-out practice, we have what you need.

150-FGT | Flange and Gasket Training System

Bayport Technical's Flange and Gasket Trainer (150-FGT) is designed to incorporate air and water pressure with numerous industry typical blind flanges, gaskets, flanged ports and valves to simulate field conditions in a variety of exercises involving craft, maintenance and safety skills with gasket selection, change procedures, torque performance, blind placement and a variety of additional training opportunities.

150-LOTO2B | Lockout Tagout Training System

This system provides hands-on safety training for a wide variety of common process activities, both mechanical and electrical. The unit is capable of demonstrating the necessary procedures of locking out different valves or parts of the equipment in order to isolate individual sections. The unit can also demonstrate electrical processes involving the isolation of switch boxes via breaker boxes and switches.

150-LOTOC | Lockout Tagout Training System

Bayport Technical's Lockout Tagout Training System, Single & Double Block & Bleed (150-LOTOC) is a set of SS LOTO tables with one single block and bleed and one double block and bleed.

150-MT | Maintenance Training System

Bayport Technical's Maintenance Training System was designed to provide hands-on training for a wide variety of common process activities. Training exercises with this unit include alignment and coupling exposure, complete pump maintenance, electric motor and associated control systems, including lock-out tag-out exercises.

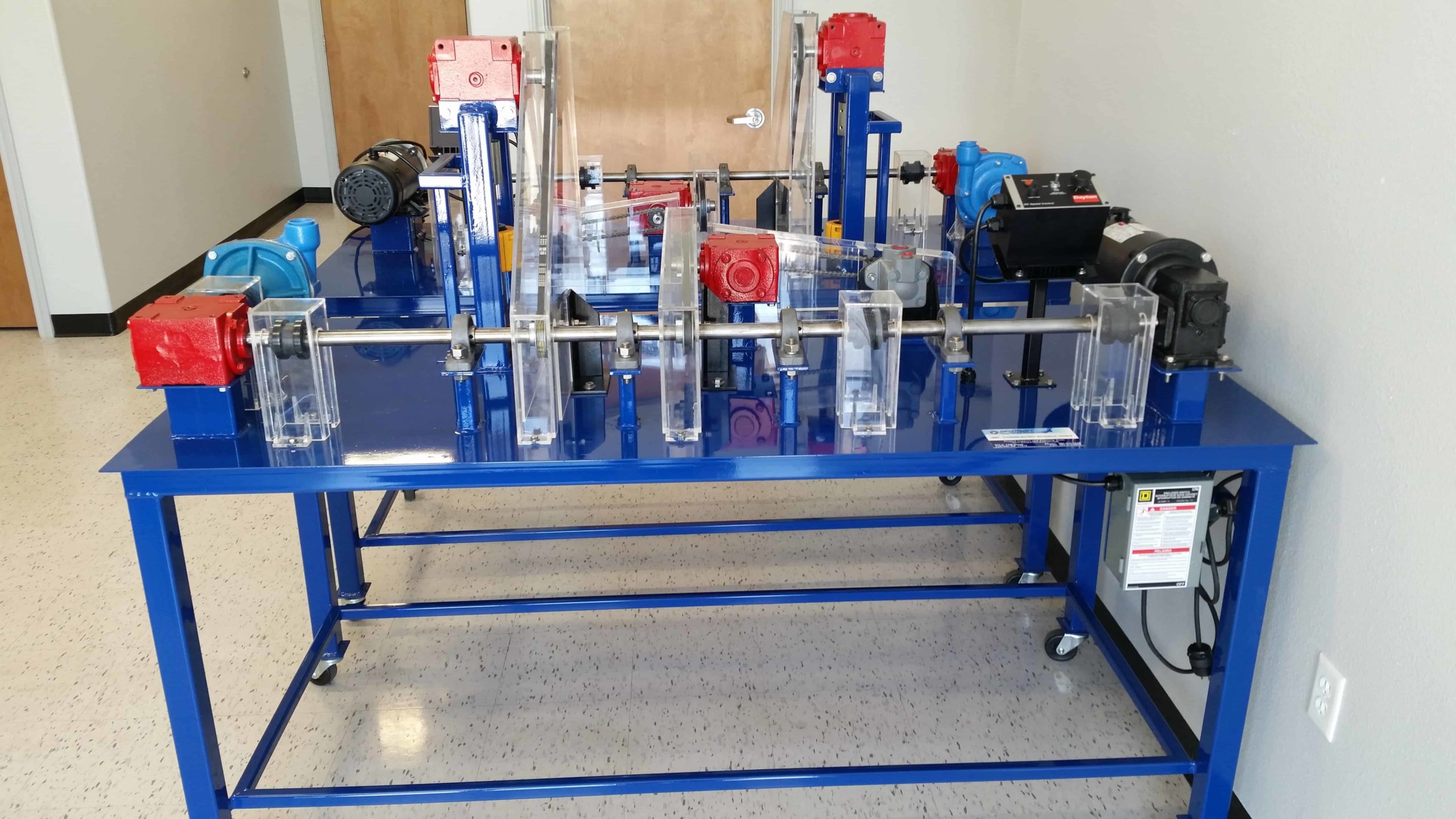

150-SMMT | Standard Multiple Mechanical Training System

Designed to provide maintenance and operations personnel with hands-on exposure to a variety of common mechanical situations inherent to industrial processes to progress through the full range of skills using one comprehensive unit. This unit can develop skill sets on vertical and various horizontal shaft alignment, gear drives, belt drives, chain drives, pump maintenance, and lock-out/tag-out.

Heat Transfer

Bayport Technical's Heat Transfer trainers teach skills related to various types of heat exchangers.

110-HECT1 | Tabletop Heat Exchanger Circulation Trainer

Bayport Technical's Tabletop Heat Exchanger Circulation Trainer (110-HECT1) is a hands-on circulation system aimed at improving student heat transfer knowledge.

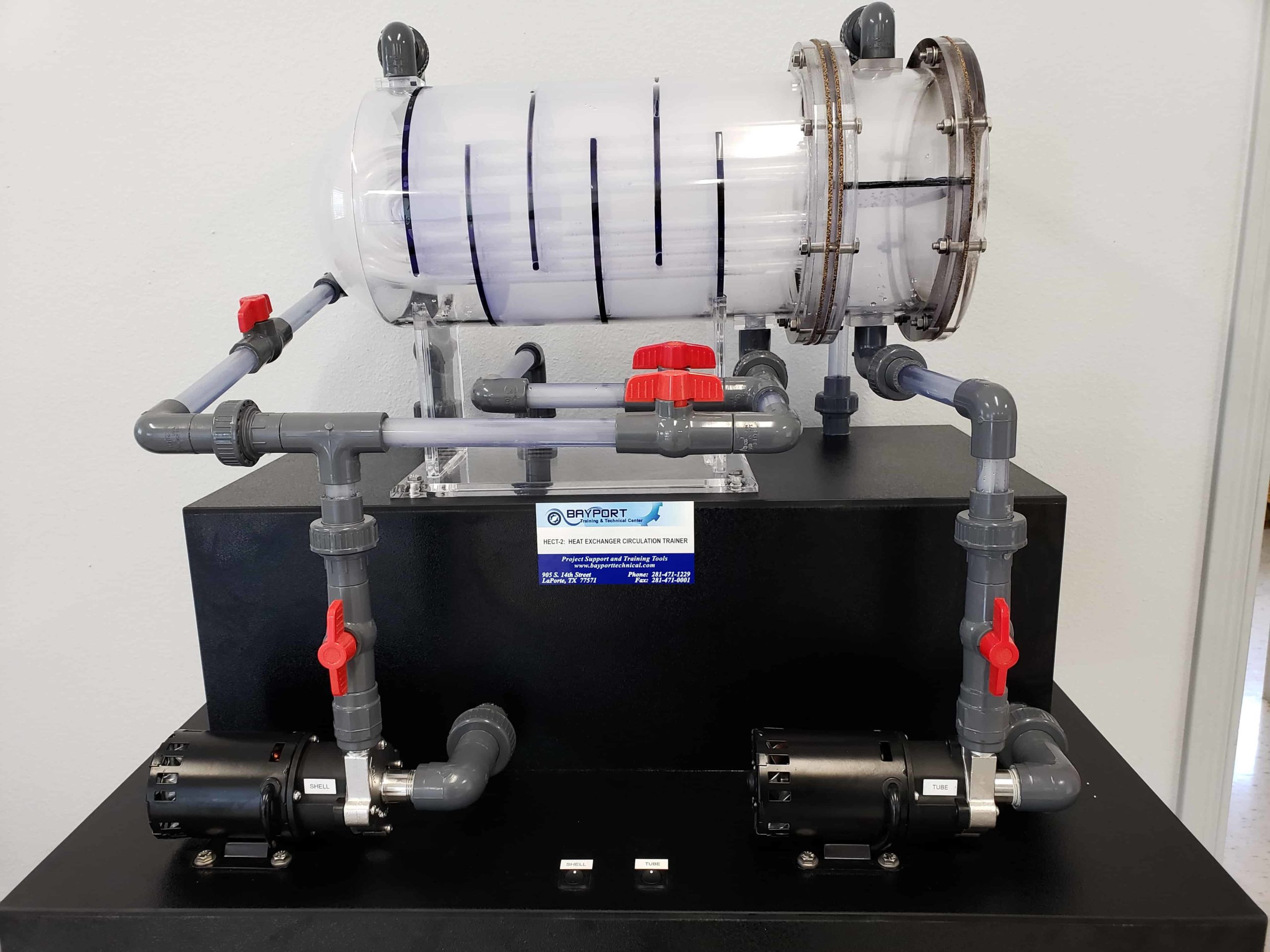

110-HECT2 | U-Tube Heat Exchanger Circulation Trainer with Backwash

A working model containing two circulation pumps and two supply tanks for demonstration. Different colored water streams are circulated from the shell side and through the tube side to simulate the working of a real heat exchanger.

110-HTDU | Heat Transfer Trainer

The Heat Transfer Trainer consists of: a chassis with casters; two pumps for hot and cold fluid, manifolded with valving; a water heater with storage tank; a refrigerant-type water chiller with storage tank; flow meters and controllers; digital thermometers; and four heat exchangers (brazed plate, brass single pass tube and shell, stainless steel single pass tube and shell, and four pass tube and shell).

Instrumentation & Process Control

Bayport Technical's Instrumentation & Process Control trainers teach hands-on skills for multiple tasks, including those associated with flow-, level-, pressure-, and temperature-controlled processes.

120-BPT | Basic Process Trainer

Designed to teach the fundamentals of process control & instrumentation. It features two ANSI process pumps, tanks and piping, level control, pressure control, flow control, temperature control, and one programmable logic controller (PLC).

120-CFLCD | Custom Flow Level Control Trainer>

The unit consists of the following main components: multiple loop programmable controller; fluid pump; orifice assembly; transmitters; control valves; fluid storage with flow tanks; heater and cooler; and pressure gauges and components. It is mounted on a cabinet base on casters.

120-CPT | Custom Process Trainer with Remote Supervision

The Custom Process Trainer with Remote Supervision features pumps, tanks, piping, level control, pressure control, flow control, temperature control, a programmable logic controller (PLC), two ANSI process pumps (mounted in parallel), an orifice flow control loop, a fixed wattage heater, and a variety of safety features.

120-IPT | Instrumentation Process Trainer

The Instrumentation Process trainer features: chassis with casters; magnetic centrifugal pump; acrylic water column; tank; 3/4 HP motor; four (4) loops with control valves and transmitters for flow, level, pressure, and temperature; HMI touchscreen and PLC; motor control center; pneumatic supply regulator and gauges; and standard operating manuals.

Oil & Gas

Bayport Technical's Oil & Gas trainers teach important skills needed by employers in the oil & gas industry.

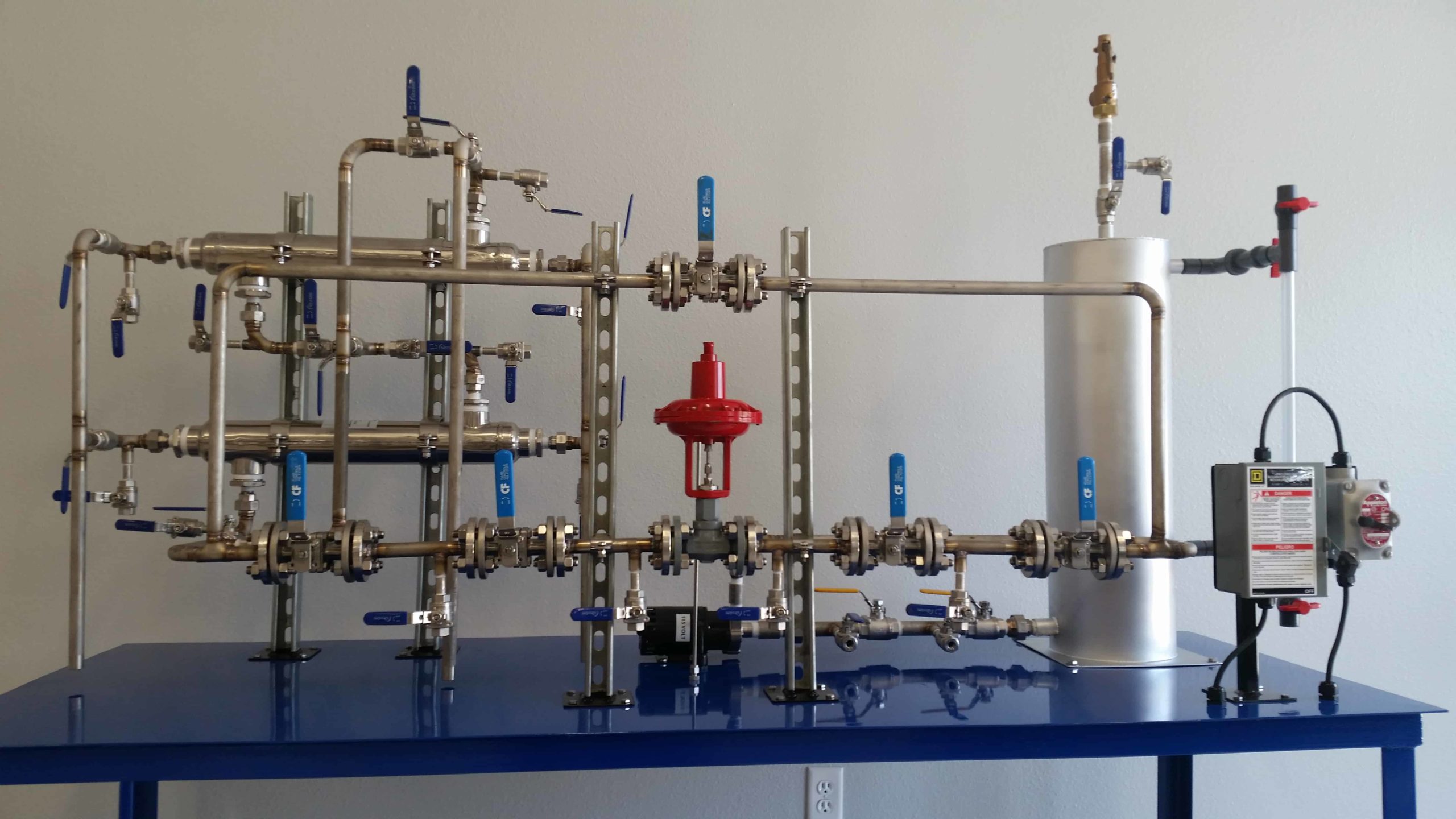

140-GLPT | Gas Lift Process Trainer

Bayport Technical's Gas Lift Process Trainer (140-GLPT) was designed specifically to illustrate the injection of gas into the production piping of wells with inadequate formation pressure to flow independently. The unit contains multiple regulators, valves, and gauges to allow for broad training opportunities associated with the up-steam arena.

Unit Operations

Bayport Technical's Unit Operations trainers teach important skills needed by operators to fully understand the systems they'll be working with. Contact Bayport Technical today for more information!

130-DTU1 | Distillation Trainer – Glass, with Chiller

Bayport Technical's Distillation Trainer - Glass, with Chiller (130-DTU1) is a full-size working glass distillation unit. The 130-DTU1 is ideal for teaching the process of distillation, incorporating a stripper column in addition to the main column. The unit also includes a custom chilled water unit. The pressure system, temperature readouts & controls, pump switch panel, and flow controls are all centrally located for ease of operation and safety.

130-DTU2 | Portable Distillation Trainer – Glass, with Chiller

The glass fractionating column allows the operator to see the results of their actions very quickly. The unit consists of the following equipment: main column, four pumps, overhead condensers, heat exchangers, cooling system, reboiler, temperature gauges, and piping. All of this equipment is intended to provide instructors with a working model of the equipment used in refineries or petrochemical plants, and accurately demonstrates distillation on a small-scale.