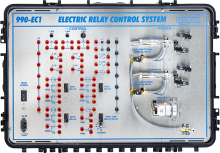

Amatrol’s Portable Electric Relay Control Troubleshooting Training System (990-EC1F) covers concepts widely used in industrial, commercial, and residential applications to regulate electric motors and fluid power actuators, as well methods used for troubleshooting problems in relay control components and systems.

Amatrol FaultPro

Amatrol’s FaultPro computer-based fault insertion software is the industry’s only electronic troubleshooting training system. FaultPro allows instructors to instantly set and tailor faults to test a student’s weaknesses and turn them into strengths. The troubleshooting skills taught by FaultPro allow students to solve real-world problems they’ll encounter on the job. FaultPro inserts electronic faults safely, protecting both students and equipment from incurring any damage.

FaultPro comes standard with more than two dozen Amatrol training systems spanning seven different technologies.

-

Item Number:990-EC1F

-

Item Number:990-PC1Amatrol’s Portable Process Control Troubleshooting Learning System – Level & Flow (990-PC1F) provides a skill-rich, portable troubleshooting training system for two of the most common types of process control systems, flow and liquid level.

-

Item Number:990-PAB53AFAmatrol’s Portable PLC Troubleshooting Learning System - AB CompactLogix L16 (990-PAB53AF) teaches programmable logic controller (PLC) programming, operation, and applications used throughout industry.

-

Item Number:990-PAB53AFAmatrol's 990-PAB53AF Portable PLC Troubleshooting Learning System provides a comprehensive curriculum and a cutting-edge workstation to teach PLC (Programmable Logic Controller) programming, operation, and applications used in industry. The 990-PAB53AF uses FaultPro, Amatrol’s unique electronic fault insertion, to teach PLC troubleshooting skills, such as PLC input and output testing, software testing, and application troubleshooting.

-

Item Number:895Amatrol’s Smart Controls Troubleshooting Workstation (895) teaches hands-on programmable logic controller (PLC) troubleshooting skills needed in various applications with Industry 4.0 technologies. Trainees will learn how to operate, program, and troubleshoot PLCs that interface with many applications, including electro-pneumatics; motor control; temperature control; variable frequency drives; smart sensors; process control; and I/O Link communications.