Amatrol Tabletop Mechatronics

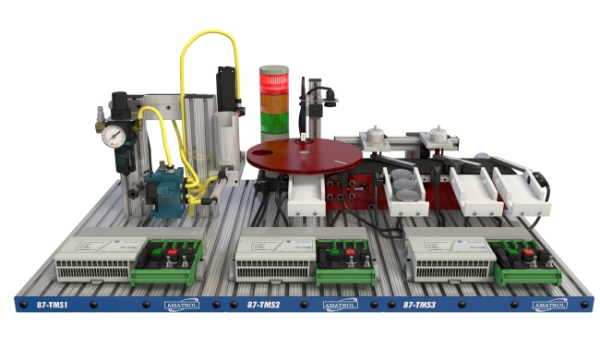

Amatrol’s Tabletop Mechatronics is a portable, durable, affordable learning system that forms a fully automated line to teach real-world mechatronics skills. This learning system features a pick-and-place, gauging, and inventory station, all of which fit on a standard tabletop! Mechatronics is an integral part of the automotive, pharmaceutical and chemical industries, to name a few. The impact and applications of mechatronics grow daily, so industries need skilled workers who understand these complex systems.

Each mechatronics station includes a PLC control unit with an AB1000 PLC, 10 inputs, 6 outputs, and much more! These stations also include a curriculum covering basic PLC programming and I/O training simulators with push-buttons, selector switches, and output indicators so learners can program and operate the PLC before moving actuators on the station.

Individual Station Detail:

Three Individual Stations Form One Mechatronics Line. Each station is a complete learning system with different technologies!

- Inventory Feeding Station (87-TMS1)

- Inspection and Indexing Station (87-TMS2)

- Sorting and Distribution Station (87-TMS3)

Station 1: Inventory Feeding (87-TMS1)

Amatrol’s Inventory Feeding Station (87-TMS1) is a portable, affordable mechatronics option that covers the vital industrial skill of using automated control to move parts from point to point. This pneumatically powered station fits on a standard tabletop and features real-world components, such as electro-pneumatic actuators, a magnetic reed switch, and a vacuum switch. The 87-TMS1 also features an AB1000 PLC, 10 inputs, 6 outputs, and much more!

The Inventory Feeding Station can be used as a stand-alone simulator to teach real-world mechatronics skills or it can be combined with the Inspection & Indexing Station (87-TMS2) and Sorting & Distribution Station (87-TMS3) to form a fully automated line!

Outstanding Automation Curriculum

The 87-TMS1’s curriculum is packed with a breadth and depth of automation topics and skills that’s unmatched in the industry. Key learning areas include: powered parts feeder operation; pick and place pneumatic manipulation; electro-pneumatic valve adjustment; stop functions; multiple actuator sequencing; and much more!

Learning Topics

- Automation Operations

- Introduction to PLCs

- Basic PLC Programming

- PLC Motor Control

- PLC Counter and Timer Instructions

- Pick and Place Feeding

- Material Feeding Systems

- Vacuum Adjustment

- Event Sequencing

- Stop Functions

- Pneumatic Manipulator Sequencing

Key Features

- Portable for Training in Multiple Settings

- Affordable Solution for Mechatronics Training

- Heavy Duty Industrial Components for Long Life

- Dual Function: Operator Station and I/O Simulator for PLC Training

Station 2: Inspection and Indexing (87-TMS2)

Amatrol’s Inspection & Indexing Station (87-TMS2) is an electrically powered learning system that focuses on how automated gauging is used to inspect parts before they move to the next step in the process. It features an electric stepper motor, three different industrial sensors, a 3-color stacklight, an AB1000 PLC, 10 inputs, 6 outputs, and much more!

The 87-TMS2 is a portable, durable, affordable solution to provide mechatronics training and build real-world skills for careers in this vital industrial area. It can be used as a stand-alone system to teach inspection and indexing skills or it can be combined with the Inventory Feeding Station (87-TMS1) and the Sorting & Distribution Station (87-TMS3) to form a fully automated line on a tabletop!

Outstanding Automation Curriculum

The 87-TMS2 curriculum features an astounding breadth and depth of automation topics and skills. Key learning areas include: index station operation; adjustment of fork, homing, and proximity sensors; stepper motor programming; homing sensor adjustment; stepper motor index table sequencing; index station sequencing; and much more!

Learning Topics

- Automation Operations

- Introduction to PLCs

- Basic PLC Programming

- PLC Motor Control

- PLC Counter and Timer Instructions

- Indexing

- Index Station Operation

- Adjustment of Fork, Homing, and Proximity Sensors

- Stepper Motor Programming

- Homing Sensor Adjustment

- Stepper Motor Index Table Sequencing

- Index Station Sequencing

Key Features

- Portable for Training in Multiple Settings

- Affordable Solution for Mechatronics Training

- Heavy Duty Industrial Components for Long Life

- Dual Function: Operator Station and I/O Simulator for PLC Training

- Safe 24 VDC Power

Station 3: Sorting and Distribution (87-TMS3)

Amatrol’s Sorting and Distribution Station (87-TMS3) teaches about robot-based inventory systems, which provide orderly and logical storage of materials. It features a conveyor, three industrial sensors, sorting chutes, electric solenoid actuators, an AB1000 PLC, 10 inputs, 6 outputs, and much more!

This durable, affordable learning system provides a portable solution for situations where mechatronics training is needed in multiple locations or when training space is limited. The 87-TMS3 can be a stand-alone system that offers real-world skills for careers in this vital industrial area or it can be combined with the Inventory Feeding Station (87-TMS1) and the Inspection & Indexing Station (87-TMS2) to form a fully automated line on a tabletop!

Automation Curriculum to Build Real-World Skills

The 87-TMS3 curriculum combines a depth and breadth of theoretical knowledge and real-world automation skills that’s unmatched in the industry. Key learning areas include: sorting module operation; parts storage operation; flat belt conveyor adjustment; sorting module sequencing; multiple station operation; and much more!

Learning Topics

- Automation Operations

- Introduction to PLCs

- Basic PLC Programming

- PLC Motor Control

- PLC Counter and Timer Instructions

- Sorting and Parts Storage

- Sorting Module Operation

- Parts Storage Operation

- Flat Belt Conveyor Adjustment

- Thru-Beam Photoelectric Adjustment

- Sorting Module Sequencing

- Multiple Station Operation

Key Features

- Portable for Training in Multiple Settings

- Affordable Solution for Mechatronics Training

- Heavy Duty Industrial Components for Long Life

- Dual Function: Operator Station and I/O Simulator for PLC Training

- Safe 24 VDC Power

Outstanding Automation Curriculum

The 870-PTAB10′s curriculum features an astounding breadth and depth of automation topics and skills. Key learning areas include: control system concepts, mechatronics safety, programmable controllers, PLC programming language, PLC program analysis, motor control basics, program development, timer instructions, time-driven sequencing, and much more!

Key Features:

- Portable for Training in Multiple Settings

- Affordable Solution for Mechatronics Training

- Heavy Duty Industrial Components for Long Life

- Plug and Play Interchangeable Controllers

- Dual Function: Operator Station and I/O Simulator for PLC Training

- Safe 24 VDC Power

- Pneumatic and Electric Stations

- Three Individual Stations Form One Mechatronics Line

- Outstanding Automation Curriculum

Learning Topics

- Automation Operations

- Mechatronics Safety

- Introduction to PLCs

- PLC Programming Languages

- Basic PLC Programming

- PLC Program Analysis

- PLC Motor Control

- Seal-In Program Logic

- PLC Counter and Timer Instructions

- Count Up Instructions

- Pick and Place Feeding

- Vacuum Adjustment

- Event Sequencing

- Stop Functions

- Indexing

- Stepper Motor Programming

- Sorting and Parts Storage

- Flat Belt Conveyor Adjustment