Centrifugal Pump Learning System

The model 950-PM1 Pumps Learning System teaches skills related to centrifugal pumps, which are used in almost every industry to transfer non-hydraulic fluids of various types from one place to another. Students learn a comprehensive set of industry-relevant skills including how to operate, install, maintain, troubleshoot, analyze performance, and select centrifugal pumps as well as system design.

The model 950-PM1 includes a centrifugal pump, mobile test workstation, student learning materials for both theory and lab, and teacher’s guide. This system uses industrial quality components such as a cast iron centrifugal pump to help students become better prepared for what they will encounter on the job.

The mobile test workstation includes complete instrumentation to enable students to learn how centrifugal pumps perform under the various load conditions. Instruments include: inlet and outlet pressure gauges, digital flow meter, motor speed readout, and torque readout. The system is also equipped with various devices to enable students to recreate the wide variety of conditions under which pumps typically operate. These include: load valve, air ingestion valve, cavitation valve, and variable speed motor.

Many additional types of pumps are also available to extend the learning capabilities of the 950-PM1 Pump Systems. The 950-PM1 workstation and piping design enable students to mount these other pumps through a universal pump mounting unit and flexible piping connections. Students can also mount a second pump to the workstation to test the operation of series (multi-stage) and parallel pump operation.

Online eBooksReference GuideRequirementsOptional Online eBooks

As an online option to the Learning Activity Packets (LAPs) Amatrol’s eBooks look like a real book and allow users to flip between pages with ease. Enhanced with features, such as keyword searches and zoom controls, that enable a user to quickly locate and view information make these eBooks a great learning tool. Available online through Amatrol’s Learning Management System (LMS), this comprehensive curriculum advances students’ understanding of concepts at the click of a button. High quality graphics paired with hands-on, applied skills keep students focused and engaged in their work. Amatrol’s eBooks allow courses to be taken completely online anywhere with an internet connection!

Student Reference Guide

A sample copy of this course’s Student Reference Guide is included with the learning system. Sourced from the multimedia curriculum, the Student Reference Guide takes the entire series’ technical content contained in the learning objectives and combines them into one perfect-bound book. If you would like to inquire about purchasing additional Student Reference Guides for your program, contact your local Amatrol Representative for more information.

Additional Requirements

- Electricity (208 VAC/60 Hz/1 phase)

- Water (30 gallons)

- Hand Tool Package (41213)

- Corrosion Inhibitor (18619)

Learning Topics

- Concept of Head

- Mechanical Seal Installation and Replacement

- Pump Sizing and Selection

- Centrifugal Pump Installation Start-up

- Cavitation

- Priming

- Air Ingestion

- Performance Measurement

- Pump Safety

- Centrifugal Pump Operation

- Pump Alignment

- Maintenance

- Mechanical Seal Operation and Maintenance

- Centrifugal Pump Construction

- Centrifugal Pump Performance

Key Features

- Variable Speed Pump Drive

- Industrial Quality Centrifugal Pump with Foot Mount and Mechanical Seal

- Fault Insertion - Air Ingestion Valve

- Fault Insertion - Cavitation Valve

- Flexible Piping Network for series/parallel pumps

- Speed/Torque/Flow/Head measurement

- Load Valve for performance measurement

- Flexible Piping Network to mount other pumps

- Optional Online eBooks

- Student Reference Guide

Product Options

- Pumps System eBooks (E18610)

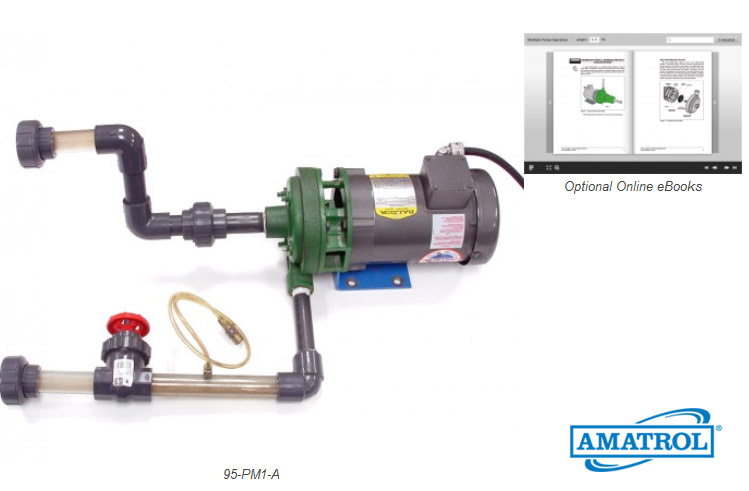

- Multiple Pump Learning System (95-PM1-A)

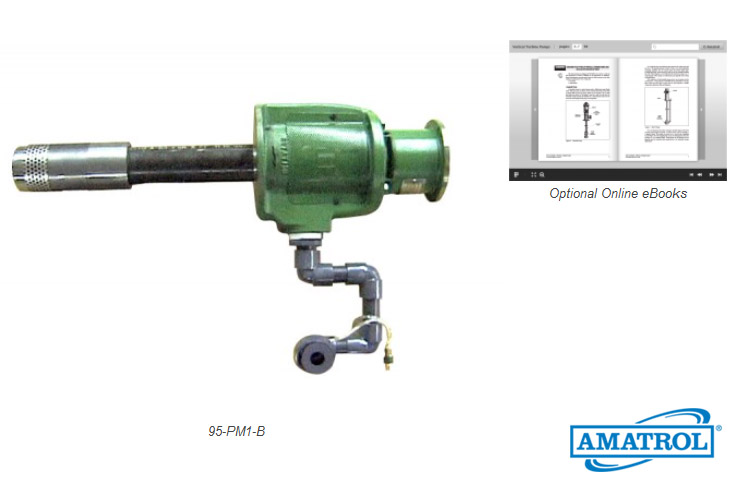

- Turbine Pump Learning System (95-PM1-B)

- Diaphragm Pump Learning System (95-PM1-C)

- Peristaltic Pump Learning System (95-PM1-D)

- Piston Pump Learning System (95-PM1-E)

- Gear Pump Learning System (95-PM1-F)

- Magnetic Pump Learning System (95-PM1-G)

- Centrifugal Pump with Stuffing Box Learning System (95-PM1-H)

Pumps System eBooks (E18610)

Centrifugal Pumps From Operation to Troubleshooting!

The Pumps Systems curriculum teaches skills related to centrifugal pumps, which are used in almost every industry to transfer non-hydraulic fluids of various types from one place to another. Students learn a comprehensive set of industry-relevant skills including how to operate, install, maintain, troubleshoot, analyze performance, and select centrifugal pumps as well as system design. (References 950-PM1)

Pump Systems eBooks Allow Online Access to Curriculum!

Amatrol’s eBooks look like a real book and allow users to flip between pages with ease. Enhanced with features such as keyword searches and zoom controls that enable a user to quickly locate and view information, these eBooks are a fantastic learning tool.

Amatrol’s eBooks are available online and can be used by anyone with access to Amatrol’s Learning Management System (LMS). Optionally, if you choose to use your own LMS, these eBooks are SCORM compatible to allow smooth integration into your current training system. Combined with our already extensive library of interactive multimedia titles, which are also SCORM compatible, users can now complete their entire course work online!

Key Features

- Strong Depth and Breadth of Content

- Built for Self-Paced Learning

- Easy, Quick Navigation

- Searchable Course Content

Multiple Pump Learning System (95-PM1-A)

Amatrol’s Multiple Pump Learning System (95-PM1-A) adds onto the 950-PM1 by including an additional centrifugal pump and electric motor, which allows students to study the functions and real world applications of series and parallel pumps. The 95-PM1-A presents practical skills such as installing and operating series and parallel pumps with theoretical knowledge like measuring and graphing flow/pressure characteristics and calculating pump efficiency.The 95-PM1-A includes an industrial-grade, close-mount centrifugal pump/ electric motor and a piping network. By supplying real-world components, Amatrol proves why it’s the world’s leader in skills-based, interactive technical learning by allowing students to practice on mechanisms they’d normally only find on the job, which develops both experience and confidence.

Once this learning system is completed, students can continue to increase their knowledge of pump systems by advancing to the Turbine Pump Learning System (95-PM1-B) and Diaphragm Pump Learning System (95- PM1-C). Turbines are used for high flow, low pressure transfer of fluids from one point to another, especially for applications where contamination is a concern, and air-operated diaphragm pumps are used to transfer fluids that are too viscous, corrosive, abrasive, or hot for other types of pumps.

Key Features

- Flexible Piping Network

- C-Face Mount and Mechanical Seal

- Industrial Quality Centrifugal Pump

- Load Valve for performance measurement

- Optional Online eBooks

Turbine Pump Learning System (95-PM1-B)

The Turbine Pump Learning System (95-PM1-B) explores an exceptionally versatile pump that’s used in many environments, such as water treatment plants, paper mills, ski resorts, farms, and airports. When integrated with the 950-PM1, the 95-PM1-B allows students to study different types of turbine pumps, their functions and applications, and their flow/pressure characteristics. The 95-PM1-B also explains how to install, maintain, troubleshoot, and disassemble a turbine pump.

The 95-PM1-B includes an industrial-grade turbine pump (cast iron housing, flange mount, stuffing box-type seal) and piping network. These industrial-grade components form a durable learning system that provides students with real-world experience and skills.

After completing the 95-PM1-B, Students can proceed to additional pumps like the Diaphragm Pump (95-PM1-C) and Peristaltic Pump (95-PM1-D). Air-operated diaphragm pumps are used to transfer fluids that are too viscous, corrosive, abrasive, or hot for other types of pumps, and peristaltic pumps, also known as tubing pumps, are used to transfer fluids that cannot come in contact with the working parts of the pump, either to avoid contamination of the fluid or because the fluid is too corrosive.

Key Features

- Quick Connect Piping to 950-PM1 Workstation

- Industrial Quality Vertical Turbine Pump

- Mounting Compatible with 950-PM1 Workstation

- Optional Online eBooks

Diaphragm Pump Learning System (95-PM1-C)

The Diaphragm Pump Learning System (95-PM1-C) explains the function, operation, application, and variety of diaphragm pumps. Diaphragm pumps are used to transfer fluid that’s too viscous, corrosive, abrasive, or hot for other types of pumps, making it a perfect choice for moving food products such as peanut butter, ink for the print industry, and pulp, paper, and petroleum products. The 95-PM1-C also explores how to adjust a diaphragm pump flow rate, how to select the right diaphragm pump for an application, and how to install, maintain, disassemble, and troubleshoot a diaphragm pump.

The 95-PM1-C features a foot-mounted, air-operated diaphragm pump, air regulator, air lubricator, pressure gauge (0-160 psig), air muffler, and piping network. These industrial-grade components will help to familiarize students with actual mechanisms they’ll work with on the job. This commitment to providing high quality components is why Amatrol is the world’s leader in skills-based, interactive technical learning.

After completion, students can proceed to additional pumps like the Peristaltic Pump (95-PM1- D) and Piston Pump (95-PM1-E). Peristaltic pumps, also known as tubing pumps, are used to transfer fluids that cannot come into contact with the working parts of the pump, either to avoid contamination of the fluid or because the fluid is too corrosive. Piston pumps, also known as plunger pumps, are used to produce high pressure fluid flow of water, soaps and detergents.

Key Features

- Mounting Compatible with 950-PM1 Workstation

- Double Diaphragm Design

- Industrial Quality Diaphragm Pump

- Quick Connect Piping Connections to 950-PM1

- Optional Online eBooks

Peristaltic Pump Learning System (95-PM1-D)

The Peristaltic Pump Learning System (95-PM1-D) covers the function, operation, and maintenance of peristaltic pumps, which are used in a variety of applications within the chemical, food, pharmaceutical, and biotechnological industries. This versatile pump keeps fluid uncontaminated as it moves through the system by utilizing a tubing system that prevents direct contact with the pump’s working parts. As an example, peristaltic pumps are used to filter and circulate blood throughout the body during heart surgery. The 95-PM1-D also discusses peristaltic pump components, how to reduce pulsation, how to calculate and adjust the flow rate, and how to select proper tube sizes.

The 95-PM1-D features a foot-mounted peristaltic pump with polycarbonate housing and steel pump head, a maintenance key tool, and a piping network. The 95-PM1-D’s industrial-grade components are the same as those used in the field, so students will gain experience and practice on actual, real-world mechanisms.

Once completed, students can proceed to additional pumps like the Piston Pump (95-PM1-E) and the Gear Pump (95-PM1-F). Piston pumps are used in water, soap, and detergent applications to produce high pressure fluid flow. Gear pumps transfer fluids under pressure and are used in hydraulic systems, pressure washing, and liquid recirculation.

Key Features

- Mounting Compatible with 950-PM1 Workstation

- Industrial Quality Peristaltic Pump

- Quick Connect Piping Connections to 950-PM1

- Optional Online eBooks

Piston Pump Learning System (95-PM1-E)

The Piston Pump Learning System (95-PM1-E) provides students with an in-depth overview of the piston pump, which has been in use longer than any other type of pump. The piston pump produces high pressure fluid flow of water, soaps and detergents in various applications within the aerospace, marine, agriculture, and auto industries. Within the world-class curriculum, students will study set-up, operation, flow/pressure characteristics, maintenance, and troubleshooting for this highly efficient pump. Students will also study how to connect the pump to a motor, how to adjust the flow rate, and how to calculate theoretical and actual flow rates.

The 95-PM1-E consists of a piston pump with cast iron housing, twin piston design, and torque arm mounting, a relief valve, and a piping network. This industrial-grade equipment is an example of Amatrol’s commitment to providing top-notch components and curriculum that allows students to gain both a theoretical background and hands-on practice in their chosen course.

After completing the 95-PM1-E curriculum, students can expand their education to pumps like the Gear Pump (95-PM1-F) and the Magnetic Pump (95-PM1-G). Gear pumps transfer fluids under pressure and are used in hydraulic systems, pressure washing, and liquid recirculation. Magnetic pumps use a magnetic coupling between the drive shaft and the impeller wheel that prevents fluid from coming into contact with the working parts of the pump.

Key Features

- Mounting Compatible with 950-PM1 Workstation

- Twin Piston Design

- Industrial Quality Diaphragm Pump

- Quick Connect Piping Connections to 950-PM1

- Optional Online eBooks

Gear Pump Learning System (95-PM1-F)

The Gear Pump Learning System (95-PM1-F) covers the function, operation, installation, and maintenance of the versatile gear pump. This low maintenance pump can transfer a wide array of fluids and fluid viscosities for spraying, recirculating, cleaning, and fluid transfer applications. One of the most common applications of a gear pump is in an automobile’s automatic transmission. This learning system also provides information on how to inspect, disassemble, and troubleshoot the pump; how to select the proper gear pump for an application; and how to calculate theoretical and actual flow rates.

The 95-PM1-F consists of a gear pump with bronze gears and bronze housing, relief valve, flexible-type coupling half, and piping network. These industrial-grade components are an example of Amatrol’s commitment to providing top-flight equipment and gives students the opportunity to practice and gain experience on actual mechanisms that they’ll work with on the job.

After completing the 95-PM1-F curriculum, students can continue by studying the Magnetic Pump Learning System (95-PM1-G). Magnetic pumps prevent fluid from coming into contact with the working parts of the pump, either to avoid contamination of the fluid or because the fluid is too corrosive. Magnetic pumps are used in chemical, food, pharmaceutical, and biotechnology applications.

Key Features

- Quick Connect Piping Connections to 950-PM1

- Mounting Compatible with 950-PM1 Workstation

- Rotary Gear Design

- Industrial Quality Gear Pump

- Optional Online eBooks

Magnetic Pump Learning System (95-PM1-G)

The Magnetic Pump Learning System (95-PM1-G) covers the magnetic pump, which uses a magnetic coupling to prevent direct contact between the motor drive shaft and the pump impeller. This feature eliminates any possibility of leakage or seepage and makes the magnetic pump an ideal selection for pumping hazardous chemicals that could harm the environment or for expensive liquids where it is important to reduce loss. The 95-PM1-G curriculum explains the function, operation, installation, disassembly, inspection, and maintenance of a magnetic pump. Additional topics include: how to properly align the magnetic coupling; how to troubleshoot problems; how to select the correct magnetic pump for an application; how to determine a pump’s flow/pressure characteristics; and how each component of the pump factors into the overall operation.

The 95-PM1-G includes a polypropylene housed, c-face mounted magnetic pump with a centrifugal impeller, a piping network, a magnetic coupling, and a relief valve. The polypropylene housing is chemically resistant, which allows the magnetic pump to move fluids such as acids, alkalis, plating solutions, sterile solutions, and brine for applications in hospitals, chemical laboratories, and wineries. In fact, all of the included components are industrial-grade and will allow students to gain immediate hands-on experience and practice that can apply to real-world mechanisms. This commitment to providing learns with top-flight equipment is one reason why Amatrol is the world’s leader in skills-based, interactive technical learning.

Key Features

- Mounting Compatible with 950-PM1 Workstation

- Magnetic Coupling Design

- Industrial Quality Magnetic Pump

- Optional Online eBooks

Centrifugal Pump with Stuffing Box Learning System (95-PM1-H)

The Centrifugal Pump with Stuffing Box Learning System (95-PM1-H) covers a pump design that, in spite of the modern mechanical seal, remains widely used in industry due to its cost-effectiveness and ability to avoid catastrophic failure. This feature makes it an ideal design for fire departments in fire pump applications. The 95-PM1-H explains the installation, function, and maintenance of a centrifugal pump with a stuffing box. Additional topics include: how to troubleshoot this pump design; what the flow/pressure characteristics of a centrifugal pump are; and how to start-up and operate a centrifugal pump with a stuffing box.

The 95-PM1-H includes a cast iron-housed centrifugal pump with stuffing box and a piping network that features a pressure line, suction line, and pressure gauge hose. These components allow students to practice skills on an industrial-grade centrifugal pump that they may work with at real-world job sites. This commitment to providing students with the most realistic and applicable training available is one example of how Amatrol is transforming the global workforce one life at a time.

Key Features

- Industrial Quality Centrifugal Pump

- Mounting Compatible with 950-PM1 Workstation

- Stuffing Box - Packing Type Seal

- Optional Online eBooks

More Information

Amatrol offers an extensive line of learning systems for pump operation, installation, maintenance, and construction. Visit Amatrol to learn more.