Amatrol Turbine Electric Hub Troubleshooting Learning System

Wind turbine electric hubs present unique operation and maintenance challenges. Wind turbine technicians must be able to pinpoint and resolve a wide variety of situations where the hub is key, especially in changing load conditions. Their troubleshooting and problem-solving skills have to be excellent to effectively handle their jobs and keep wind turbines operational.

The 950-TEH1 allows students to develop and practice component, subsystem, and system-level skills. It is fully functional like a utility-scale turbine electric hub. The Turbine Electric Hub Troubleshooting Learning System includes Amatrol’s unique electronic fault insertion system, which allows instructors to electronically create realistic hub problems and then track the student’s progress in fixing it. Additionally, the 950-TEH1 will connect to Amatrol’s 950-TNC1 Turbine Nacelle Learning System to create a complete wind turbine learning experience.

The 950-TEH1 is an effective training platform for wind turbine technicians. The Turbine Electric Hub Troubleshooting Learning System includes a mobile workstation, blade simulator with a 3-axis servo system, pitch control unit, emergency power unit, blade simulator, pitch control software, fault insertion system, PC-based multimedia curriculum, and an instructor’s guide. Amatrol’s 950-TEH1 provides essential skills for wind turbine technicians.

Real World, Utility Scale Turbine Electric Hub Experience

Amatrol’s Turbine Electric Hub Troubleshooting Learning System enables students to develop operation skills essential to wind turbine technicians. The system features pitch control software that enables a student to learn how to start-up, test, and shut-down the hub portion of wind turbine systems. The 950-TEH1 includes major components found in utility scale wind turbine electric hubs such as a pitch control unit, pitch control software, electric servo drives, brakes, slip ring, battery-powered emergency power unit, pitch position encoders, and feather position sensors. The system features 3 axes so students can gain a visual understanding of the synchronized positioning of blade operation.

Computer Based Fault Insertion Across All Key Subsystems

Troubleshooting skills are essential for wind turbine technicians. At the heart of teaching troubleshooting skills is the ability of an instructor to create realistic problems or faults that students must identify and resolve. It is what they will have to do, by themselves, on top of a wind turbine tower. The 950-TEH1 includes over 30 faults distributed across all key subsystems – electrical and mechanical. This will allow instructors to create realistic troubleshooting situations that a wind turbine technician will encounter on the job.

Amatrol uses electronic fault insertion so that instructors can easily insert faults and track the student’s troubleshooting results. Electronic fault insertion prevents component damage while allowing instructors to see student progress. Instructors can identify specific areas the student needs to improve and target those areas. It also allows instructors to set-up faults ahead of time, allowing students to perform self-directed study when appropriate.

Links to Amatrol’s 950-TNC1 Turbine Nacelle Troubleshooting and 950-TGC1 Turbine Generator Control Learning Systems

While an independent learning system, the 950-TEH1 will also link to Amatrol’s 950-TNC1 Turbine Nacelle Troubleshooting and Turbine Generator Control Learning Systems. These three systems combine to create a realistic operating and troubleshooting wind turbine environment. Fiber optic communications connect the controls of the three systems and control the entire system using the turbine control software, just as they would on a real wind turbine. Students can actually bring the turbine online with the grid.

Multimedia Curriculum Available

Amatrol’s unmatched multimedia utilizes text, audio, and stunning 3D animations that engage learners in both theoretical knowledge and hands-on skills. This thorough, exceptionally detailed curriculum is built to begin with the basics and steadily advance to more complex concepts and skills. Through partnerships with key industry leaders and leading-edge educators, Amatrol developed the right balance of knowledge and applied skills needed to train learners to work in their chosen field.

Student Reference Guide

A sample copy of this course’s Student Reference Guide is included with the learning system. Sourced from the multimedia curriculum, the Student Reference Guide takes the entire series’ technical content contained in the learning objectives and combines them into one perfect-bound book. If you would like to inquire about purchasing additional Student Reference Guides for your program, contact your local Amatrol Representative for more information.

Product Options

- Turbine Electric Hub Multimedia (M20013)

- Turbine Nacelle Troubleshooting Learning System (950-TNC1)

- Wind Concepts Learning System (950-WC1)

- Wind Turbine Generator Control Troubleshooting Learning System (950-TGC1)

Turbine Electric Hub Multimedia (M20013)

Turbine electric hub troubleshooting teaches the unique operation and maintenance challenges of a utility scale electric hub. Learners acquire knowledge of adaptive skills for wind turbine operation, adjustment of electric hubs, and troubleshooting in a wide variety of situations. Provides overview of component, sub-system, and system level skills needed for hub operation in a wide variety of situations where the hub is key, especially in changing load conditions. Covers hub power and safety, pitch control, servo pitch operation, emergency feather, battery types, banks, operation and capacity, power voltage verification, blade troubleshooting.

Engaging Multimedia

Amatrol’s extensive, thorough multimedia covers green energy basics such as turbine electric hub troubleshooting. Interactive screens paired with instructive graphics teach turbine electric hub topics from hub operation to battery power. With the optional hardware, learners can then apply this theoretical knowledge to immediate hands-on skills. For example, learners study the functions of a servo pitch operation and then manually test a wind turbine electric servo pitch system for applied practice. This combination of theory and practice ingrains concepts in a learner’s mind and makes more advanced topics easier to comprehend. (References 950-TEH1)

Turbine Nacelle Troubleshooting Learning System (950-TNC1)

Operating and maintaining utility-scale wind turbine nacelle systems requires unique skills. A wind turbine technician handles a wide breadth of operational and maintenance issues at the top of hundred-meter towers. Their troubleshooting and problem-solving skills have to be excellent to effectively handle their jobs and keep wind turbines operational.

Amatrol’s 950-TNC1 Turbine Nacelle Troubleshooting Learning System teaches students adaptive skills for wind turbine operation, adjustment, and troubleshooting in a wide variety of situations. The 950-TNC1 allows students to develop and practice component, sub-system, and system-level skills. It is fully functional like a utility-scale nacelle. The Turbine Nacelle Troubleshooting Learning System includes Amatrol’s unique electronic fault insertion system, which allows instructors to electronically create realistic nacelle problems and then track the student’s progress in fixing it. Additionally, the 950-TNC1 will connect to Amatrol’s 950-TEH1 Turbine Electric Hub Learning System as well as the 950-TGC1 Turbine Generator Control Learning System to create a complete wind turbine learning experience.

The 950-TNC1 is an effective training platform for wind turbine technicians. The Turbine Nacelle Troubleshooting Learning System includes a mobile workstation, turbine control unit, nacelle module, hydraulic brake system, wind simulator, monitoring, and control software, fault insertion system, PC-based multimedia curriculum, and an instructor’s assessment guide. Amatrol’s 950-TNC1 provides essential skills for wind turbine technicians.

Real World, Utility-Scale Wind Turbine Nacelle Experience

Amatrol’s Turbine Nacelle Troubleshooting Learning System enables students to develop operation and troubleshooting skills essential to wind turbine technicians. The system features turbine control software that enables a student to learn how to start-up and shutdown wind turbine systems. The 950-TNC1 includes major components found in utility-scale wind turbines such as a turbine control unit, hydraulic system with cartridge valves, brakes, yaw drive with dual motor drive, twistbox, and an ultrasonic anemometer. The wind simulator allows students to test the operation of the system under varying wind speed and direction conditions, teaching students to operate the yaw control and turbine safely.

Computer Based Fault Insertion Across All Key Subsystems

Wind turbine technicians must have good troubleshooting skills. At the heart of teaching troubleshooting skills is the ability of an instructor to create realistic problems or faults that students must identify and resolve. It is what they will have to do, by themselves, on top of a wind turbine tower. The 950-TNC1 includes over 30 faults distributed across all key subsystems – electrical, mechanical, and hydraulic. This will allow instructors to create realistic troubleshooting situations that a wind turbine technician will encounter on the job. Amatrol uses electronic fault insertion so that instructors can easily insert faults and track the student’s troubleshooting results. Electronic fault insertion prevents component damage while allowing instructors to see student progress. Instructors can identify specific areas the student needs to improve and target those areas. It also allows instructors to set-up faults ahead of time, allowing students to perform self-directed study when appropriate.

Links to Amatrol’s 950-TEH1 Turbine Electric Hub Troubleshooting and 950-TGC1 Turbine Generator Control Learning Systems

While an independent learning system, the 950-TNC1 will also link to Amatrol’s Turbine Electric Hub (950-TEH1) and Turbine Generator Control (950-TGC1) Learning Systems. These three systems combine to create a realistic operating and troubleshooting wind turbine environment. Fiber optic communications connect the controls of the three systems and control the entire system using the turbine control software, just as they would on a real wind turbine. Students can actually bring the turbine online with the grid.

Multimedia Curriculum Available

Amatrol’s unmatched multimedia utilizes text, audio, and stunning 3D animations that engage learners in both theoretical knowledge and hands-on skills. This thorough, exceptionally detailed curriculum is built to begin with the basics and steadily advance to more complex concepts and skills. Through partnerships with key industry leaders and leading-edge educators, Amatrol developed the right balance of knowledge and applied skills needed to train learners to work in their chosen field.

Student Reference Guide

A sample copy of this course’s Student Reference Guide is included with the learning system. Sourced from the multimedia curriculum, the Student Reference Guide takes the entire series’ technical content contained in the learning objectives and combines them into one perfect-bound book. If you would like to inquire about purchasing additional Student Reference Guides for your program, contact your local Amatrol Representative for more information.

Key Features

- Links to 950-TEH1 and 950-TGC1

- Computer Based Fault Insertion

- Utility Scale Wind Turbine Experience

Learning Topics

- Yaw System Operation

- Meteorological Instrumentation

- Yaw Brakes

- Nacelle Components & Operation

- Turbine Control Functions, Software, Power

- Twist Box

- Turbine Safety

- Parking Brakes

- Safety Loop Operation

- Turbine Hydraulics

- Turbine Control Unit

- Rotor Lock

- System Communications

- Yaw Drive

- System Troubleshooting

Turbine Nacelle Troubleshooting Learning System Product Information

Wind Concepts Learning System (950-WC1)

Wind energy is a significant source of power whose use is growing dramatically. The Department of Energy has set a goal for 20% of electrical energy used in the United States to be from wind power by 2030. Wind farms can be found throughout the world – from cold, arctic conditions to the tropics, from beaches to mountains to oceans. Understanding the basics of how we can harness wind energy is essential for technicians, engineers, installers, designers, builders, and others who want to apply wind technology either in large utility-scale turbine farms or in small wind applications.

Amatrol’s 950-WC1 Wind Concepts Learning System introduces students to a broad range of basic concepts in wind energy technology. Students learn how wind power systems work and what it takes to generate electrical power with wind. The 950-WC1 acts as a foundation for students enrolled in wind-specific as well as general renewable energy programs. Wind Concepts includes student curriculum in PC-based, interactive multimedia format as well as an instructor’s assessment guide.

Using Wind Technology to Capture Wind Energy

Siting a wind farm or turbine is important. With utility-scale wind turbines costing several million dollars, understanding how much energy you can produce from the turbine in a specific location is key. The amount of wind available at different heights varies tremendously as you can see from the wind resource map at right. In the 950-WC1, students gain knowledge and skills in applying science and mathematical skills. Amatrol’s Wind Concepts teaches students about many of the factors involved in the critical turbine siting decision.

The Many Types of Wind Power Systems

Wind power is harnessed by a broad array of wind power systems. The most striking difference is between residential or small wind and utility-scale turbines. While each have their place in the energy landscape, they are very different in both application and design. Understanding the fundamentals of these various systems and how they are used is a good base from which to launch a strong knowledge of wind power. Amatrol’s 950-WC1 Wind Concepts teaches students about the range of wind power systems and how they are applied.

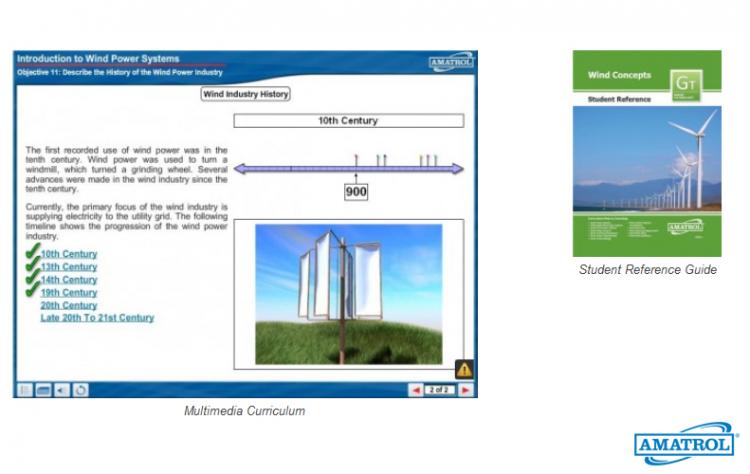

Multimedia Curriculum

Amatrol’s unmatched multimedia utilizes text, audio, and stunning 3D animations that engage learners in both theoretical knowledge and hands-on skills. This thorough, exceptionally detailed curriculum is built to start with the basics and advance to more complex concepts and skills. Through partnerships with key industry leaders and leading-edge educators, Amatrol developed the right balance of knowledge and applied skills needed to train learners to work in their chosen field.

Student Reference Guide

A sample copy of this course’s Student Reference Guide is included with the learning system. Sourced from the multimedia curriculum, the Student Reference Guide takes the entire series’ technical content contained in the learning objectives and combines them into one perfect-bound book. If you would like to inquire about purchasing additional Student Reference Guides for your program, contact your local Amatrol Representative for more information.

Key Features

- Interactive, Engaging Multimedia

- Types of Wind Power Systems

- Wind Technology to Capture Wind Energy

Learning Topics

- Wind Resources

- Wind Resource Measurement

- Wind Power Systems

- Utility-Scale Wind Power Systems

- Wind Power Industry

- Small Wind Power Systems

- Wind Turbine Aerodynamics

- Wind Power Characteristics

- Wind Turbine Ratings

- Wind Turbine Capacity & Availability

- Wind Plant Siting

- Wind Plant Economics

Wind Turbine Generator Control Troubleshooting Learning System (950-TGC1)

The generator control system is the heart of a utility-scale wind turbine, converting mechanical rotation of the hub into clean, 3-phase power that synchronizes with the utility grid. To operate and maintain a wind turbine effectively, wind turbine technicians must have the special skills needed to service, operate, and troubleshoot the generator control system, which includes the generator, rectifier, generator control unit, power distribution panel, pad mounted transformer, and generator control software.

The 950-TGC1 Turbine Generator Control Troubleshooting Learning System teaches students adaptive skills for generator system operation, adjustment and troubleshooting in a wide variety of situations. It allows students to develop and practice component and system level skills and gives them the classroom instruction and hands-on experience they need to succeed in the emerging and growing field. The Turbine Generator Control Troubleshooting Learning System includes Amatrol’s unique electronic fault insertion system, which allows students to experience troubleshooting of realistic generator control problems and receive automatic feedback on their progress.

The 950-TGC1 provides an effective training platform with a workstation containing a fully-operational generator system; fault insertion system; PC-based interactive, multimedia curriculum; instructor’s assessment guide; and installation guide. Additionally, the 950-TGC1 connects to the Amatrol’s Nacelle and Hub workstations to create a comprehensive wind turbine learning laboratory.

Real World, Utility Scale Turbine Generator Control Experience

Amatrol’s Turbine Generator Control Troubleshooting Learning System enables students to develop operation and troubleshooting skills for wind turbine generator control systems. The system features generator control software that enables a student to learn how to start-up, test, and shut-down the wind turbine systems. The 950-TGC1 includes major components and circuitry found in utility scale wind turbine generator control systems such as a generator control unit, power distribution panel, transformer, transducers, main line contactor, power factor correction capacitor network, inductive filter, revenue meter, shunt trip circuit breaker, and 3-phase inverter.

Computer Based Fault Insertion Across All Key Subsystems

Troubleshooting skills are essential for wind turbine technicians. At the heart of teaching troubleshooting skills is the ability of an instructor to create realistic problems or faults that students must identify and resolve. It is what they will have to do, by themselves, on top of a wind turbine tower. The 950-TGC1 includes 29 faults including six different types of faults: Operational, Bus, Line, Drive, Temperature, and Generator faults. This will allow instructors to create realistic troubleshooting situations that a wind turbine technician will encounter on the job. Amatrol uses electronic fault insertion so students can easily insert faults and track the student’s troubleshooting results. Electronic fault insertion prevents component damage while allowing instructors to see student progress. Instructors can identify specific areas the student needs to improve and target those areas. It also allows students to perform self-directed study.

Links to Amatrol’s Nacelle and Hub Troubleshooting Learning Systems

While an independent learning system, the 950-TGC1 will also link to Amatrol’s 950-TNC1 Turbine Nacelle Troubleshooting and the 950-TEH1 Turbine Electric Hub Troubleshooting Learning Systems. These three systems combine to create a realistic operating and troubleshooting wind turbine environment. Fiber optic communications connect the controls of the three systems and control the entire system using the turbine control software, just as they would on a real wind turbine. Students can actually bring the turbine online with the grid.

Multimedia Curriculum Available

Amatrol’s unmatched multimedia utilizes text, audio, and stunning 3D animations that engage learners in both theoretical knowledge and hands-on skills. This thorough, exceptionally detailed curriculum is built to begin with the basics and steadily advance to more complex concepts and skills. Through partnerships with key industry leaders and leading edge educators, Amatrol developed the right balance of knowledge and applied skills needed to train learners to work in their chosen field.

Student Reference Guide

A sample copy of this course’s Student Reference Guide is included with the learning system. Sourced from the multimedia curriculum, the Student Reference Guide takes the entire series’ technical content contained in the learning objectives and combines them into one perfect-bound book. If you would like to inquire about purchasing additional Student Reference Guides for your program, contact your local Amatrol Representative for more information.

Key Features

- Real World, Utility Scale Turbine Generator Control Experience

- Computer Based Fault Insertion Across All Key Subsystems

- Links to Amatrol’s Nacelle and Hub Troubleshooting Learning Systems

Learning Topics

- Generation System Operation

- Commissioning Tests

- Troubleshooting

- Grid Power Interface

- Fiber Optic Communications

- Generator Control Software

- Revenue Meters

- Shunt Trip Circuit Breakers

- Line Contactors

- 3-Phase Inverters

- Power Distribution Panel

- Pad Mounted Transformers

- Rectifiers

- Computer Control Units

- Temperature Control

Wind Turbine Generator Control Troubleshooting Learning System Product Information

Key Features

- Links to 950-TNC1 and 950-TGC1

- Computer Based Fault Insertion

- Utility Scale Turbine Electric Hub Experience

Learning Topics

- Hub Functions

- Hub Safety

- Pitch Control Software

- Hub Power

- Servo Pitch Operation

- Servo Reference Position Adjustment

- Sensor Operation

- Emergency Feather Operation

- Battery Operation & Capacity

- Battery Types & Banks

- Battery Charging

- Emergency Feather Control

- Power Voltage Verification

- Hub Fault Messages

- Individual Blade Troubleshooting

- System Troubleshooting

- Battery Maintenance