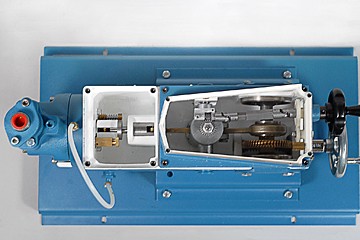

Hydraulic Diaphragm Metering Pump Cutaway, Lost Motion Adjustment Type

DAC Worldwide’s Hydraulic Diaphragm Metering Pump Cutaway, Lost Motion Adjustment Type (278-170) depicts a sectioned positive-displacement pump, which allows for realistic classroom or lab training in the operation, construction, and maintenance of common metering or controlled volume pumps used in various sectors across the world.

Selected and assembled to support introductory process operations and maintenance training programs, this real-world learning solution provides the same utility in on-the-job equipment. The full-size, fully-detailed example of a real-world metering pump gives learners a first-hand view of a component found in various applications worldwide.

All pump components have been retained, allowing for a complete, one-of-a-kind training experience using these common pieces of process equipment.

The Hydraulic Diaphragm Metering Pump Cutaway, Lost Motion Adjustment Type provides a realistic training-introduction to horizontal diaphragm metering pump components. The pump’s components are industrial-grade, made by leading manufacturers, mimicking what students might encounter on the job for industrial relevancy.

Various carefully-planned cut way areas and color-coding combine to showcase the internal configuration of the pump. A hand crank allows observation of the pump's method of converting rotary motion to reciprocating motion and the lost-motion mechanism used for stroke adjustment.

This specialty turbine pump cutaway will enhance general and plant-specific operations and maintenance training programs. Additionally, the equipment used within the trainer is cleaned, primed, and painted using a high-endurance urethane coating, providing durability to stand up to frequent use.

Features and Specifications

- Sectioning of an actual industrial reciprocating pump. Pumps by Pulsa and others are chosen for industrial relevance.

- Multiple sectioned areas are provided, allowing for viewing of all internal components, and mechanisms

- Handwheel, allowing for observation of rotary/reciprocating motion

- Cleaning, priming, and painting using a high-durability urethane coating

- Color-coding of cutaway surfaces, seal elements, internal mechanical components, and interior surfaces using contrasting colors

- Replacement plated hardware, where needed

- All gaskets, seals, and bearings visible

- 7-Gauge formed-steel, powder-coated baseplate

- Packaging for shipment via motor freight

- Product Dimensions (L x W x H): 13.5in x 24in x 15in

- Shipping Dimensions (L x W x H): 15in x 28in x 24in

- Recommended #902F - Electromechanical Workstation