Smart Factory Training

Amatrol’s “Smart Factory” training system is a fully connected and flexible manufacturing system that connects its physical systems, operational information, and human assets to control manufacturing, maintenance, inventory, and supply chain operations. Amatrol’s in-depth curriculum teaches all aspects of smart factory maintenance and operation in a self-directed, interactive format.

Smart Factory Skills are Key to a Rewarding Career!

Smart factories require highly trained technicians that can set up, operate and maintain all aspects of these systems. Amatrol’s self-paced, interactive curriculum, provides individuals with the tools needed to prepare them for a successful career in this field.

Amatrol offers two options:

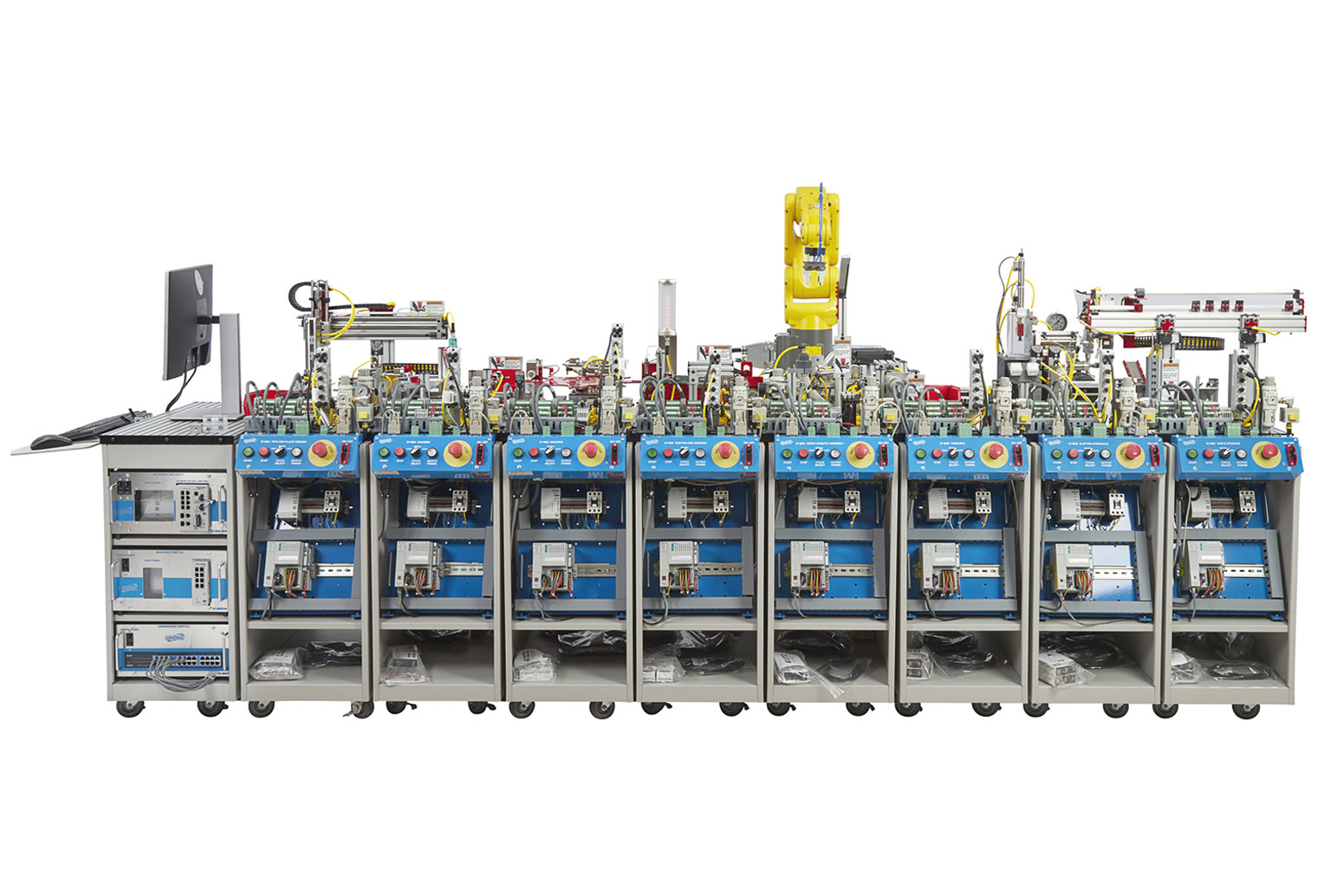

Smart Factory Mechatronics Training System

Amatrol’s Smart Factory Mechatronics Training System is an eight-station automated manufacturing line that assembles a functional, two-way pneumatic valve. This system utilizes either a FANUC LR Mate robot or an Amatrol Pegasus robot, iGear Squeaks software for Smart Factory communication, Allen-Bradley and/or Siemens PLCs, and a ninth cart that houses systems for Ethernet (87-EN), Wireless Communication (87-WL), and Network Security (87-NS) training. Each of the eight main stations of the Mechatronics System features a smart sensor or component for Smart Communication, including pneumatic/vacuum, ultrasonic, photoeye, stack light, electrical current, and analog pressure.

Smart Factory Tabletop Mechatronics Training System

Amatrol’s Smart Factory Tabletop Mechatronics System provides an option for when training space is too limited for the full Mechatronics line, but Smart Factory training remains necessary. Smart Factory Tabletop Mechatronics is a fantastic option for introducing Industry 4.0 training into high schools. This five-station system connects with Amatrol’s Portable PLC Troubleshooting Learning System – AB Compact Logix (990-PABCL1F), which shows system performance analysis via I/O Link. Performance analysis information includes transmitter pressure, photoeye signal strength, material type for parts passing through the system, RFID tag output, and more! This system also includes Smart Factory components for Ethernet (87-TEN), RFID/Sensors (87-TMS5), Barcode (87-TBR), and more!

Smart SensorsSmart Product IDNetwork CommunicationsNetwork SecuritySmart ProductionSmart Maintenance

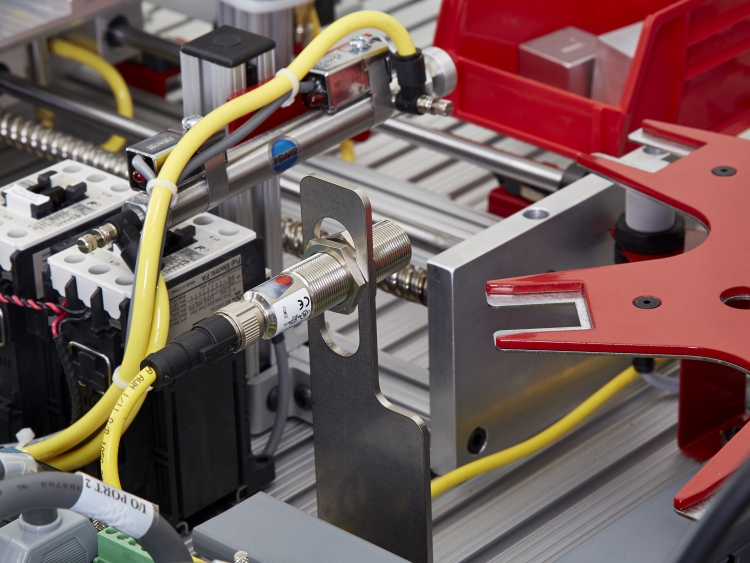

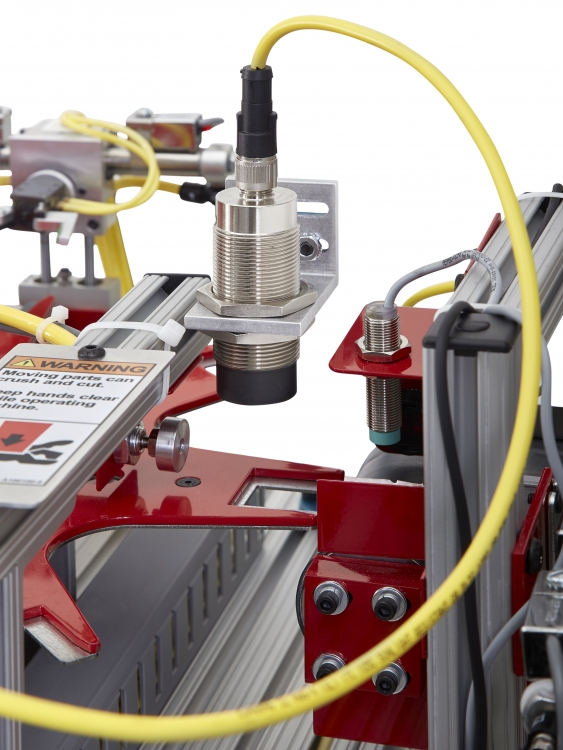

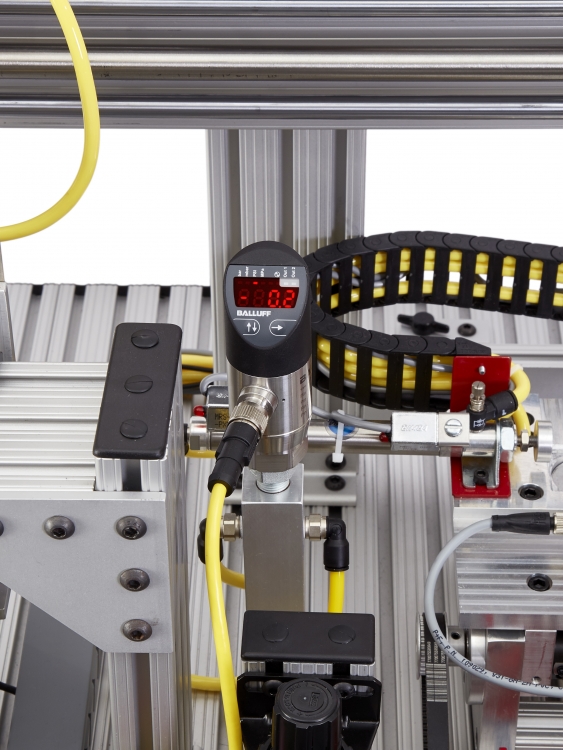

Smart Sensors

Amatrol utilizes multiple smart devices on the Smart Factory that communicate via Ethernet and I/O Link protocol providing flexible manufacturing, predictive maintenance, and data analytics capabilities.

The following learning systems teach communications between intelligent automation devices using PROFINET with Siemens PLCs and EtherNet/IP with Allen-Bradley PLCs in a Smart Factory environment with the specified sensors and components:

- Smart Factory Sensor Learning System, Pneumatics / Vacuum Sensor (87-SN1)

- Smart Factory Sensor Learning System, Ultrasonic Sensor (87-SN2)

- Smart Factory Sensor Learning System, Photoeye (Photoelectric Sensor) (87-SN3)

- Smart Factory Smart Device Learning System, Stack Light (87-SN4)

- Smart Factory Sensor Learning System, Electrical (Current Monitoring Devices) (87-SN6)

- Smart Factory Sensor Learning System, Analog Position Sensor (87-SN7)

- Smart Factory Sensor Learning System, Analog Pressure (Pneumatic Pressure Sensor) (87-SN9)

Smart Product ID

Amatrol’s Smart Factory incorporates smart product identification devices, such as vision systems and bar code readers, which trigger “intelligent” actions including parts tracking, production history, sorting, part accept/reject, & inventory control.

- Mechatronics Barcode Learning System (87-BR2): teaches programming and operation of barcode reading identification systems and communications with other intelligent automation devices using EtherNet/IP or PROFINET in a Smart Factory environment

- Smart Factory RF Identification Learning System (87-RF1): teaches programming and operation of radio frequency identification (RFID) systems and communications with other intelligent automation devices using PROFINET or EtherNet/IP in a Smart Factory environment

- Mechatronics Vision Inspection Learning System (87-VS1): teaches the use of machine vision systems in smart factory applications

Network Communications

Amatrol’s communication system connects students with a fully functional production system using industrial protocols for real-time control, program transfer, data collection, and changing programs on the fly.

- Mobile Workstation – Smart Factory Communications (87-MS1A): provides integrated organization of Smart Factory communications modules, including but not limited to wireless communication modules, managed and unmanaged network switch modules, network security modules, and master PC.

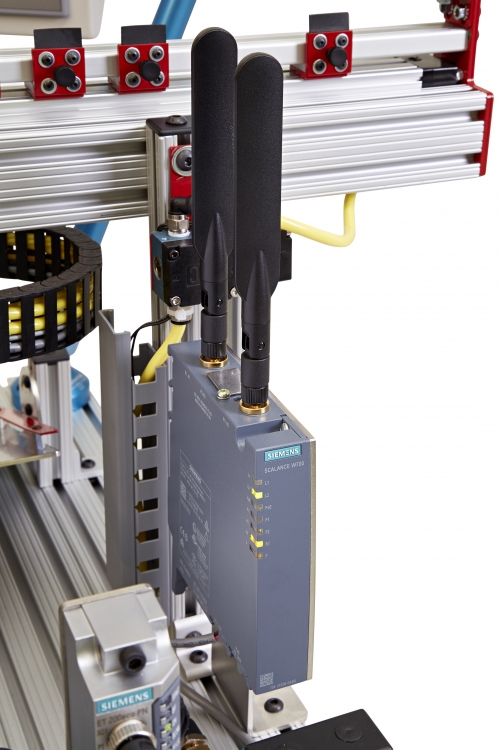

- Mechatronics Wireless Communications Learning System (87-WLAS) [U.S. Customers Only]: teaches wireless communications in a Smart Factory environment.

- Smart Factory PROFINET Learning System (87-EN): teaches communications between various intelligent automation devices in various topologies in a Smart Factory environment to efficiently control and monitor an automated manufacturing process.

- Mechatronics HMI Terminal Learning System (87-HMI): teaches the use of a human-machine interface (HMI) panel in Smart Factory applications by providing a means to operate and monitor status of smart factory processes.

- PLC Learning System (87-IOS): teaches programming and operation of industrial PLCs, either a Siemens S7-1500 or an Allen-Bradley CompactLogix L16

Network Security

Amatrol’s network security system teaches how to keep data safe and securely extend operational data to suppliers and customers. Communications security protects the smart factory from unauthorized outside access & provides secure data communications between the plant-wide network and the internet.

- Smart Factory PROFINET Network Security Learning System A (87-NS1): teaches network security for communications in a Smart Factory environment

Smart Production

Amatrol’s Smart Production software teaches how smart factories perform customized (personalized) manufacturing and make data and data analytics available via the internet to improve system performance. Amatrol’s Smart Factory assembles a pneumatic valve in various configurations based on orders entered. The valve can be ordered with a plastic or metal valve body and a 3-way or 4-way spool.

Smart Maintenance

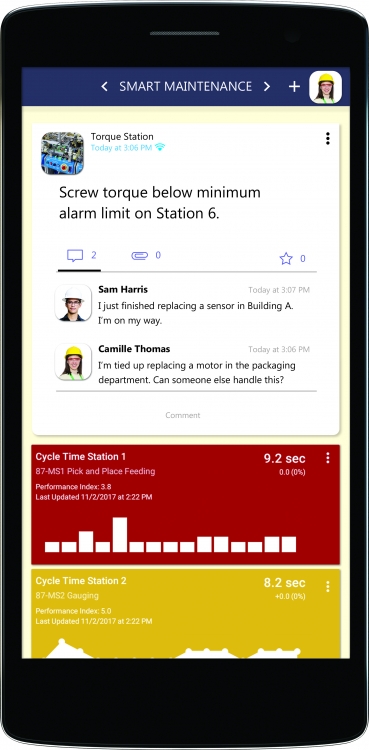

Smart Maintenance software utilizes smart device information to trigger maintenance operations automatically. Amatrol’s Smart Factory uses industry-standard software to connect users directly to the automated system and each other to create a real-world environment where maintenance team members can collaborate to resolve issues quickly and effectively.

- Smart Factory Visual Communications Learning System (87-VC): teaches web-based maintenance communications in Smart Factory applications.

- Smart Factory Manufacturing Execution Learning System (87-ME): teaches the use of web-based production control, scheduling, and monitoring in Smart Factory applications.

- Mechatronics Troubleshooting Learning System (87-FTS): teaches troubleshooting of mechatronics systems and components by presenting students with faults inserted into a live mechatronics system through a computer-controlled fault insertion system.