Stereolithography

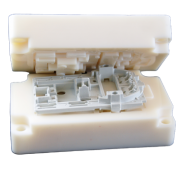

Stereolithography is an additive manufacturing process that uses a vat of liquid UV-curable photopolymer resin and a UV laser to build parts one layer at a time.

Benefits of stereolithography include:

- Parts with smooth sidewall quality and detail

- Low-volume part production of complex geometries

- Tight tolerances, layer thickness of between 50 to 200 microns

- Versatile range of materials for specific applications

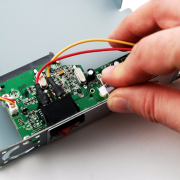

Stereolithography is commonly used as a prototyping technology within industries that need to print parts or models to validate fit form and function or for concept visualization. Stereolithography is also used in manufacturing applications for short-run part production, such as vacuum castings, injection mold tooling, investment casting master patterns, and functional end-use part production for certain environments.

Due to its competitive build times and the superior quality of the finish straight off the machine, very little post-processing is required, providing cost savings and reduced lead times.

Materials

-

Somos Momentum was developed in collaboration with footwear manufacturers to create a solution that prints tools with high accuracy, quality and fine feature detail.

-

Somos NeXt provides the accuracy of stereolithography with the look, feel, and performance of a thermoplastic. Somos NeXt is nearly indistinguishable from finished traditional thermoplastics, with the toughness, durability, and accuracy not traditionally seen in stereolithography resins.

-

Somos PerFORM is the material of choice for applications that require strong, stiff, high-temperature resistant composite parts. With its excellent high heat tolerance, outstanding detail resolution and stiffness, Somos PerFORM is the ideal material for a variety of applications.

-

Somos® PerFORM Reflect utilizes patented new technology that reduces and can even eliminate the finishing work required by traditional materials. Somos® PerFORM Reflect produces strong, stiff, temperature-resistant composite parts ideal for wind tunnel testing.

-

Somos ProtoGen 18420 is an easy-to-print, ABS-like photopolymer that produces accurate parts ideal for general-purpose applications. It offers superior chemical resistance, a wide processing latitude, and excellent tolerance to a broad range of temperatures and humidity during and after the build.

-

For applications in automotive and aerospace, Somos ProtoTherm 12120 delivers high temperature resistance with exceptional surface finishing and superior dimensional stability, making parts more robust.

-

Somos Taurus brings a combination of thermal and mechanical performance that previously was not possible with stereolithography materials. Its robustness combined with a charcoal gray appearance makes it ideal for the most demanding functional prototyping and even end-use applications.