Stereolithography

Stereolithography is an additive manufacturing process that uses a vat of liquid UV-curable photopolymer resin and a UV laser to build parts one layer at a time.

Benefits of stereolithography include:

- Parts with smooth sidewall quality and detail

- Low-volume part production of complex geometries

- Tight tolerances, layer thickness of between 50 to 200 microns

- Versatile range of materials for specific applications

Stereolithography is commonly used as a prototyping technology within industries that need to print parts or models to validate fit form and function or for concept visualization. Stereolithography is also used in manufacturing applications for short-run part production, such as vacuum castings, injection mold tooling, investment casting master patterns, and functional end-use part production for certain environments.

Due to its competitive build times and the superior quality of the finish straight off the machine, very little post-processing is required, providing cost savings and reduced lead times.

Materials

-

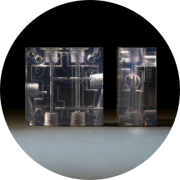

Somos® WaterClear Ultra 10122 is a low-viscosity material that produces accurate, functional parts that simulate an acrylic appearance with minimized finishing requirements. The material is ideal for applications that require optical clarity, like fluid flow analysis, master patterns and concept and functional models.

-

Somos® WaterShed AF is a multi-purpose stereolithography resin that meets the requirements for investment casting patterns as it has been designed without antimony to address sensitivities in the casting of certain specialty alloys.

-

With similar properties and processing to Somos® WaterShed XC 11122, Somos WaterShed Black is a stereolithography resin that produces rigid, tough parts in a true black color, with no need for painting.

-

Somos® WaterShed XC 11122’s ABS and PBT-like properties for stereolithography technology make it a popular resin among designers. Somos® WaterShed produces detailed parts with superior clarity and water resistance, well-suited to fluid flow analysis.

-

With mechanical properties that mimic many engineering plastics, parts created from Somos® 9120 exhibit superior fatigue properties, strong memory retention and a good balance of properties between rigidity and functionality.

-

Somos® BioClear is specially developed for medical applications, meeting the requirements for non-implantable limited body contact (less then 24hr) medical and dental applications.

-

Somos® DMX SL™ -100 is a durable and tough stereolithography material that enables production of complex, hollow composite parts in days thanks to a unique and cost-effective ‘dry removal’ process - and all with no compromise...

-

Somos Element was developed in close interaction with customers, pattern makers and foundries for printinginvestment casting patterns. The antimony-free stereolithography material improves the repeatability and quality of 3D printed casting patterns.

-

Somos® EvoLVe 128 is a durable stereolithography material that produces accurate, highly detailed parts and is designed for easy finishing. Ideal applications include tough, functional prototypes, snap-fits and jigs & fixtures.

-

Somos GP Plus 14122 is a low viscosity stereolithography resin with an opaque white appearance. This material mirrors production plastics like ABS and PBT, making it an ideal choice for virtually any application.